Aluminum Heat Sinks Customization Manufacturer in China

Optimize your thermal management systems with Xingyong, a leading expert in aluminum heat sinks.

14 extruders producing diverse with 3000-ton monthly output

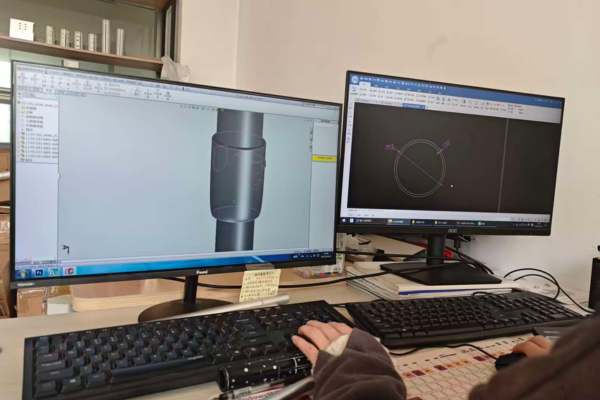

Advanced CNC and anodizing for ready-to-use custom

ISO-certified China factory delivering durable worldwide

What are Aluminum Heat Sinks

Aluminum heat sinks are metal cooling devices used to stop electronics from overheating. They work by absorbing heat from hot parts, like computer chips or LED lights, and releasing it into the air. Manufacturers choose aluminum because it is lightweight, affordable, and has excellent thermal conductivity. These parts often feature fins to increase the surface area, which helps cool things down faster. From simple extruded aluminum heat sinks to complex shapes, they are essential for keeping your devices safe and efficient.

| Attribute | Detail |

|---|---|

| Product Name | Custom Extruded Aluminum Heat Sinks |

| Material / Alloy | 6000 Series: 6063, 6061, 6005, 6082 (T5 / T6) |

| Manufacturing Process | High-Precision Hot Extrusion (350T – 2000T Press) |

| Deep Processing | CNC Machining, Drilling, Tapping, Milling, Cutting, Punching |

| Profile Shapes | Flat, Round, Square, Comb, Pin-Fin, Needle, or Custom Design |

| Dimensions (CCD) | Max Circumscribing Circle Diameter up to 250mm (Customizable) |

| Surface Treatment | Anodizing, Sandblasting, Polishing, Powder Coating, Electrophoresis |

| Color Options | Silver, Black Anodized, Gold, Blue, Red, or Custom Color |

| Length | Cutting to a specific length (Standard 3m-6m or custom short pieces) |

| Tolerance Standard | High Precision Grade (GB 5237.1-2017, EN 12020-2, ASTM B221) |

| Thermal Conductivity | ~201-210 W/(m·K) (Typical for 6063/6061 Alloys) |

| Applications | LED Lighting, Inverters, CPU, Automotive, Audio Amplifiers, Industrial |

Types categories

Explore Our Aluminum Heat Sinks Collection

At Xingyong, we offer a comprehensive range of aluminum heat sinks categorized by structural design and specific industry applications. Whether you need standard profiles or specialized components, our factory delivers precision and scalability. Browse our classifications below to find the exact thermal solution for your project requirements.

Aluminum Heat Sinks By Design & Structure

extruded heat sink

aluminium heat sink plate

finned aluminum heat sink

Round Aluminum Heat Sink

Anodized Aluminum Heat Sink

High Power Aluminum Heat Sink

large aluminium heat sink

Industrial Aluminum Heat Sink

needle aluminum heat sink

Aluminum Heat Sink By Application

LED heat sink

CPU heat sinks

inverter heat sink

heat sink automotive

Amplifier Heat Sink

heat sinks for electronics

Why Choose Xingyong Aluminum Heat Sinks

When you select Xingyong for your aluminum heat sinks, you are choosing a partner dedicated to precision and scale. Our factory transforms high-grade raw materials into superior extruded heat sink products designed for your specific electronic and industrial applications. We streamline the entire manufacturing process, offering you a stable supply chain and competitive factory-direct advantages. Reach out now to discuss your project requirements.

Powerful Extrusion Capabilities For Aluminum Heat sinks

We possess the heavy machinery required to produce aluminum heat sinks of almost any size.

14 Extrusion Presses: Equipped with machines ranging from 350T to 2000T.

High Output: Monthly production capacity reaches 3000 tons.

Versatility: Capable of producing complex cross-sections for varied industries.

Premium Alloy Materials For Aluminum Heat Sinks

We strictly use high-purity aluminum to ensure every finned aluminum heat sink delivers maximum heat dissipation for your devices.

Material Grades: Specializing in 6063 and 6061 aluminum alloys.

Conductivity: High thermal transfer rates for efficient cooling.

Durability: Excellent resistance to corrosion and wear.

One-Stop Customization Service For Aluminum Heat Sinks

We tailor every custom aluminum heat sink to fit your exact specifications.

Certified Quality Control For Aluminum Heat Sinks

Our laboratory verifies that each extruded aluminum enclosure and sink meets international standards before shipment.

Advanced Testing: Utilizing Oxford spectrometers, tensile machines, and hardness testers.

Global Standards: Certified by ISO 9001, ISO 14001, ISO 45001, and IATF 16949.

Social Compliance: Verified by BSCI and Social Audits.

FAQ of Aluminum Heat Sinks

Aluminum vs. Copper Heat Sinks: Which is better?

While copper offers higher thermal conductivity, aluminum heat sinks are generally preferred for most applications because they are significantly lighter and more cost-effective. Aluminum provides an excellent balance of performance and weight, making it ideal for automotive and consumer electronics where mass is a concern. Additionally, aluminum is easier to shape into complex finned aluminum heat sink designs compared to copper.

Why are heat sinks made of aluminum?

Manufacturers choose aluminum primarily for its thermal properties and malleability. The metal effectively absorbs heat from electronic components and dissipates it into the surrounding air. Specifically, alloys like 6063 are standard because they can be easily formed into extruded heat sink profiles with thin fins, which maximizes the surface area needed for efficient passive cooling without adding excessive cost.

How are aluminum heat sinks made?

The most common manufacturing method is extrusion. In this process, a heated aluminum billet is pushed through a steel die to create specific cross-sectional shapes. This allows for the creation of continuous aluminum heat sink bar profiles that can be cut to length. After extrusion, the parts often undergo CNC machining to add mounting holes or precise features, followed by surface treatments like anodizing.

Is aluminum a good heat sink material?

Yes, aluminum is an outstanding material for thermal management. It possesses high thermal conductivity, which allows it to transfer heat away from hot spots quickly. Furthermore, an aluminum pcb heat sink is naturally resistant to corrosion, durable, and non-magnetic. Its ability to be recycled also makes it an environmentally friendly choice for sustainable manufacturing.

Can aluminum heat sinks be anodized?

Absolutely. Anodizing is a standard finish for these products. Beyond changing the color (often to black or blue), anodizing increases the surface hardness and corrosion resistance. Crucially, black anodized aluminum heat sinks often have higher thermal emissivity than bare metal, meaning they can radiate heat more effectively, further improving cooling performance in natural convection environments.

Related Products of Aluminum Heat Sinks

Beyond aluminum heat sinks, maximize your supply chain efficiency with our durable Telescopic Poles and Aluminum Tubes. Sourcing all your industrial profiles from Xingyong ensures consistent quality and reduced logistics costs. Explore our full catalog today.

Telescopic Pool Pole

Solar Panel Cleaning Telescoping Pole

Tent Poles Aluminum (Telescoping Type)

Telescoping Pole Saw

Technical Support for Aluminum Heat Sinks

Optimize your cooling systems with our expert support. We assist in aluminum heat sinks design to solve your thermal challenges. Visit our blog for technical insights on maximizing extruded heat sink efficiency and reliability.

Contact Us

Contact Xingyong for premium aluminum heat sinks at factory prices. Submit the form for custom or bulk extruded heat sink quotes. Our team responds within 24 hours.

- No. 222, Huaihe East Road, Huaiyin District, Huaian City Jiangsu, China

- info@poolple.com

- (+86)159-9616-7132