Precision Aluminum Extrusion Enclosure Manufacturer

Xingyong provides rugged aluminum extrusion enclosure for your electronics. We deliver ready-to-assemble cases with professional finishing directly from our ISO-certified factory to your assembly line.

-

Custom lengths and CNC cutouts from a direct China manufacturer.

-

ISO 9001 and IATF 16949 certified quality for reliable electronic housings.

-

Scalable production with 14 extrusion lines for bulk orders.

What is Aluminum Extrusion Enclosure

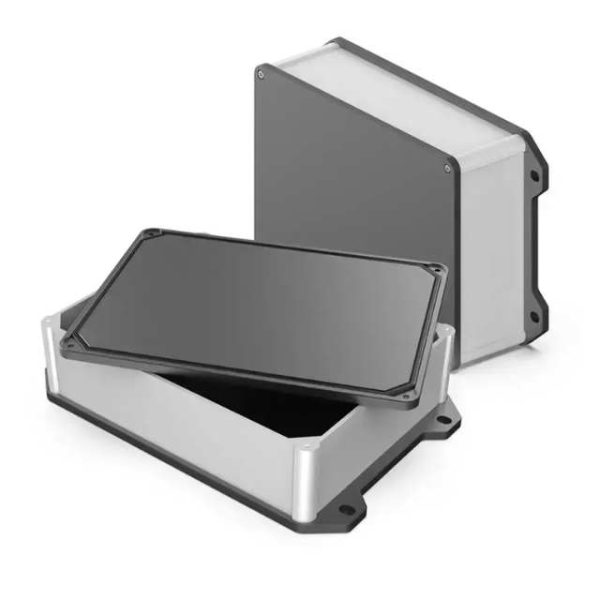

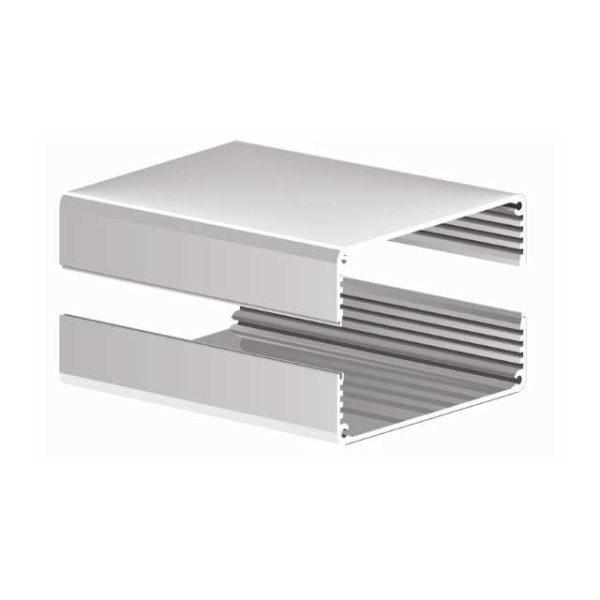

Aluminum extrusion enclosure is a strong metal housing designed to protect your electronic components. It is made by shaping aluminum alloy into a seamless profile that acts as a shield for Printed Circuit Boards (PCBs) and instruments. This type of case is excellent for cooling devices because the aluminum works as a natural heat sink. It also blocks harmful electrical interference (EMI). Manufacturers can easily cut these profiles to any custom length you need. Whether for industrial controls or DIY projects, this enclosure keeps your equipment safe, cool, and professional.

| Product Name | Custom Aluminum Extrusion Enclosure / Aluminum Housing |

|---|---|

| Material Grade | Aluminum Alloy 6063, 6061 |

| Temper | T5 (Standard), T6 (High Strength) |

| Profile Shape | Square, Rectangular, Round, Oval, or Custom Shape |

| Length | Fully Customizable (Standard cuts: 50mm – 3000mm) |

| Wall Thickness | 0.8mm – 5.0mm (Depending on profile design) |

| Dimensional Tolerance | GB/T 14846-2008 high precision grade (±0.05mm for CNC) |

| Surface Treatment | Anodizing (Class 10-25µm), Sandblasting, Powder Coating, Brushing |

| CNC Machining | Drilling, Milling, Tapping, Cutting, Punching, Laser Marking |

| IP Rating | IP40 (Standard), up to IP65/IP67 (with sealing gaskets) |

| Heat Dissipation | Excellent thermal conductivity (ideal for PCB cooling) |

| Certifications | IATF 16949:2016, ISO 9001:2015, ISO 14001, RoHS Compliant |

| Assembly Options | Split-body, Integrated (Tube), Flanged, DIN-Rail Mount |

Types categories

Explore Our Aluminum Extrusion Enclosure Series

Find the perfect housing for your electronics at Xingyong. We have organized our extensive catalog to help you quickly locate the exact aluminum extrusion enclosure you need. Whether you are looking for a specific mounting style, functional protection like waterproofing, or a solution for a particular industry application, we have you covered. Our factory uses high-quality alloy to ensure every aluminum profile enclosure is durable, precise, and ready for your components.

Aluminum Extrusion Enclosure By Installation Style

Wall Mounted Enclosures

Secure your device to walls easily with our wall mounted enclosures. These aluminum boxes feature flanges or sturdy mounting tabs, making them perfect for fixed industrial controls and safe installation in any workspace.

Din Rail Enclosure

Snap these housings onto standard rails for organized control cabinets. Our din rail enclosure solutions are perfect for automation and servers, saving space and making system upgrades quick and simple for your team.

Rackmount Case

Standard 19-inch aluminum chassis for servers and audio gear. These durable rackmount case units fit perfectly in cabinets, offering professional protection and a clean, high-end look for your heavy-duty equipment.

Handheld Enclosure

Lightweight and comfortable to hold, these cases are great for portable testing tools. Our handheld enclosure designs protect mobile electronics while providing a solid, non-slip grip for daily use in the field.

desktop enclosure instrument

Stylish housings designed for laboratory or office tables. These desktop enclosure instrument cases provide a professional appearance for medical devices and testing meters while keeping internal components safe and stable.

Aluminum Extrusion Enclosure By Function

Aluminum Waterproof Enclosure

Keep moisture and dust out with these sealed boxes. Rated IP65 or higher, our aluminum waterproof enclosure series protects outdoor electronics from rain, dirt, and harsh weather conditions effectively.

Heatsink Enclosure

Stop overheating with this finned design. The heatsink enclosure uses its aluminum body as a cooler, pulling heat away from high-power parts to keep your electronics running smoothly and safely.

Aluminum Shield

Block harmful electrical interference with our conductive metal housings. This natural aluminum shield protects sensitive data signals and prevents static noise from affecting your critical electronic circuits.

Split Body Enclosures

Two-piece design makes assembly fast and easy. With split body enclosures, you can open the case to install parts or check connections without hassle, speeding up your production line significantly.

Aluminum Extrusion Enclosure By Application

Aluminum Enclosure PCB

Custom-sized slots inside hold your circuit board firmly. This sturdy aluminum enclosure PCB shell protects delicate chips from impact and static, ensuring your custom electronic project works perfectly every time.

Aluminum Amplifier Chassis

Heavy-duty case designed for high-end audio. The aluminum amplifier chassis reduces vibration and manages heat, providing the perfect home for powerful sound systems and DIY audio amplifier projects.

Industrial Control Panel

Rugged housing for factory automation systems. These tough industrial control panel boxes protect switches and displays from dust, impact, and oil in busy manufacturing environments.

Aluminum Sensor Housing

Compact and durable protection for small detectors. Our aluminum sensor housing guards sensitive monitoring tools against damage while allowing for precise mounting in tight, limited spaces.

Power Supply Cabinet

Strong metal casing for voltage converters and batteries. The power supply cabinet offers excellent heat management and safety, keeping high-voltage equipment secure and cool during continuous operation.

Why Choose Xingyong Aluminum Extrusion Enclosure

When you partner with Xingyong, you get more than just a standard aluminum extrusion enclosure; you gain a competitive manufacturing advantage. We combine over two decades of factory experience with modern technology to deliver the exact aluminum electronic housing you envision. From melting the raw metal to the final packaged product, our team controls every step to ensure you receive consistent quality and durability. Trust us to support your business growth with a stable supply chain and expert service. Contact us today to start your project.

Large-Scale Manufacturing Power for Aluminum Extrusion Enclosure

We operate 14 advanced extrusion presses ranging from 350T to 2000T. This capacity allows us to produce aluminum extrusion box profiles of all sizes, from tiny sensor cases to large industrial chassis, ensuring we meet your volume demands.

High monthly capacity of 3000 tons ensures your large orders are delivered on schedule.

Ability to extrude complex cross-sections for unique design requirements.

Direct factory production eliminates middleman delays and reduces costs.

Premium Raw Material Selection for Aluminum Extrusion Enclosure

We use only high-grade 6xxx series alloy to manufacture your heat sink enclosure. This material selection guarantees exceptional thermal conductivity and structural integrity, which is vital for protecting your valuable electronics.

Superior heat dissipation properties to keep sensitive PCBs cool.

High resistance to corrosion ensures a long product lifespan in tough environments.

Smooth surface quality that is perfect for subsequent anodizing and painting.

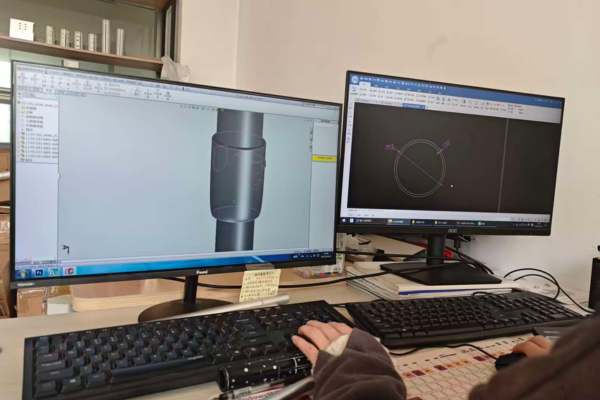

Total Customization Flexibility for Aluminum Extrusion Enclosure

Your project deserves a unique fit, and our workshop offers full customization for every custom aluminum housing. We handle everything from precise CNC machining to surface finishing in-house, giving you a product that is ready for assembly.

Precise cutouts for USB ports, switches, and connectors based on your drawings.

Custom lengths available to fit your specific circuit board without expensive new tooling.

Professional anodizing and sandblasting in various colors to match your brand identity.

Certified Quality Assurance for Aluminum Extrusion Enclosure

We hold IATF 16949 and ISO 9001 certifications to guarantee the reliability of every aluminum instrument case we ship. Our internal testing center rigorously checks each batch for hardness and dimensions before it leaves the factory.

Equipped with spectral analyzers and hardness testers for strict material verification.

Consistent color control using advanced color difference light boxes.

Full traceability of production data for your peace of mind.

FAQ Of Aluminum Extrusion Enclosure

Can you manufacture the aluminum extrusion enclosure to a custom length?

Yes, absolutely. One of the main benefits of using an extrusion profile is flexibility. We can cut the aluminum profile enclosure to your exact specified length without requiring new mold tooling. This allows you to perfectly fit your PCB or internal components. We also offer precise CNC machining to create custom holes and cutouts for your connectors and switches.

What surface finishes are available for the extruded aluminum box?

We offer a variety of professional finishes to enhance both the look and durability of your housing. The most popular choice is anodizing, which is available in clear, black, or custom colors. This process creates a hard, corrosion-resistant surface. We also provide sandblasting and powder coating options to match your specific branding requirements for the aluminum electronic housing.

How does the aluminum extrusion case handle heat dissipation?

Aluminum is naturally an excellent thermal conductor, making it the ideal material for electronics that generate heat. Many of our designs feature integrated external fins that act as a heat sink. This structure maximizes the surface area to pull heat away from your device, ensuring your heat sink enclosure keeps components cool and operational even under heavy loads.

Do you offer waterproof options for outdoor applications?

Yes, we provide waterproof aluminum enclosure solutions designed for harsh environments. These units typically include end plates with sealing gaskets and heavy-duty screws to achieve an IP65 or IP67 rating. This protection prevents dust ingress and water damage, making them suitable for industrial sensors, marine equipment, and outdoor power supplies.

What is the typical lead time for a bulk order?

Thanks to our large-scale production capacity, we can handle high-volume orders efficiently. For standard profiles that we have in stock, the turnaround is very fast. For a fully custom aluminum housing requiring specific cuts, CNC machining, and surface finishing, the lead time is generally 2 to 3 weeks after you approve the sample. We strive to support your supply chain with reliable, on-time delivery.

Related Products of Aluminum Extrusion Enclosure

While you are sourcing housing for your electronics, you might also need other high-quality aluminum products for your business. As a comprehensive manufacturer, Xingyong also specializes in Aluminum Telescopic Poles and heavy-duty Pool Cleaning Poles. These products utilize the same high-strength alloy and precision extrusion technology as our enclosures. If your product line involves cleaning tools, extension handles, or structural profiles, our factory can supply these with the same level of customization and durability. Broaden your inventory with our premium metal solutions designed for longevity and performance. Click below to view our full catalog.

Telescopic Pool Pole

Telescopic Window Cleaning Pole

Tent Poles Aluminum (Telescoping Type)

Squeegee Extension Pole

Technical Support for Aluminum Extrusion Enclosure

Do you need help selecting the right profile or designing your custom housing? Our Technical Support hub is here to guide you. We understand that choosing the correct aluminum extrusion enclosure involves considering thermal management, board fitment, and environmental protection. Visit our blog to read expert articles on “How to Calculate Heat Dissipation,” “Choosing Between Anodized vs. Powder Coated Finishes,” and “Design Tips for CNC Cutouts.” We provide the engineering insights you need to optimize your product design before mass production. Tap into our knowledge base to ensure your project succeeds from the start.

Contact Us

Need a custom aluminum extrusion enclosure? Send your drawings today for a quick factory-direct quote. We respond within 24 hours. Fill out the form now!

- No. 222, Huaihe East Road, Huaiyin District, Huaian City Jiangsu, China

- info@poolple.com

- (+86)159-9616-7132