Premium Rectangular Aluminum Tubing Manufacturer in China

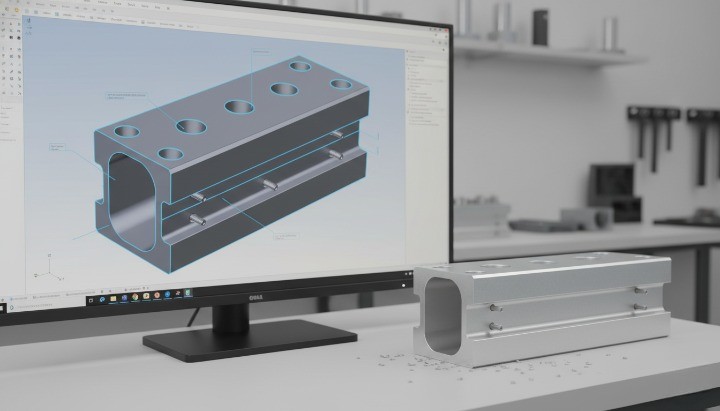

Xingyong uses 14 extrusion presses (up to 2000T) to manufacture your specific aluminum box section requirements. From heavy structural 6061 beams to precision-bent, anodized frames, we handle the complex deep processing that others cannot. Get factory-direct speed, custom sizing, and precision for your supply chain.

Custom extrusion from thin wall to large structural tubing.

In-house CNC, bending, and anodizing for finished components.

China manufacturer offering ISO-certified quality and direct factory pricing.

What is Rectangular aluminum tubing

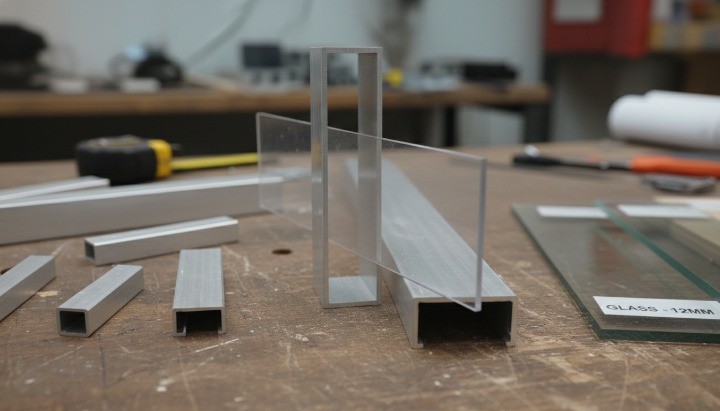

Rectangular aluminum tubing, often called aluminum box section or RHS(Aluminum rectangular hollow section), is a hollow metal shape used for building strong frames, storage racks, railings, and structural supports. It is famous for being lightweight yet very tough against rust. Most profiles use 6061 or 6063 aluminum alloys, making them perfect for structural supports, racks, and trailers. You can easily cut, weld, or paint it to fit your needs. You can also choose tubes with sharp edges or rounded corners, depending on your project.

| Property | Specification Details |

|---|---|

| Product Name | Rectangular Aluminum Tubing (Aluminum Box Section / RHS) |

| Alloy Grades | 6061, 6063, 6005, 6005A |

| Temper | T5, T6, T4, T66 |

| Standard Length | 8ft, 12ft, 20ft, 24ft (Custom cut-to-length from 10mm to 6 meters) |

| Wall Thickness | 0.040″ – 0.500″ (1.0mm – 12.0mm); Thin wall & Heavy duty available |

| Corner Type | Sharp corners (90°), Rounded corners (Radius corners) |

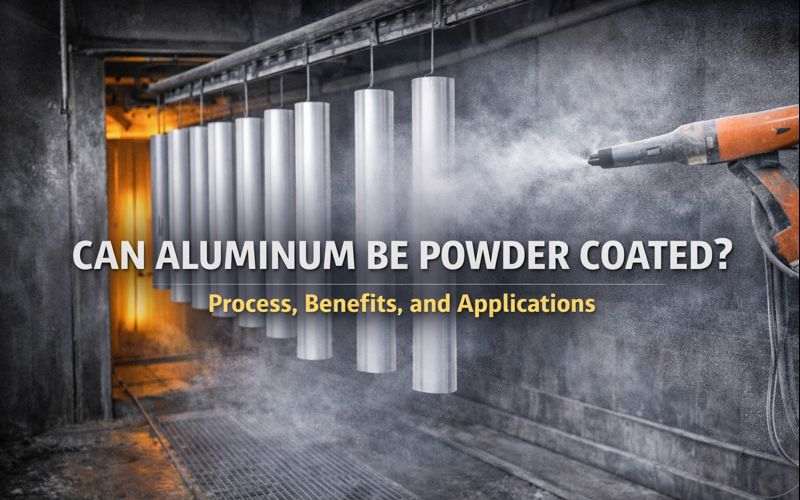

| Surface Finish | Mill Finish, Anodized (Clear, Black, Bronze), Powder Coated, Wood Grain, Polished |

| Processing Service | Bending, CNC Machining, Precision Cutting, Punching, Drilling, Tapping |

| Tolerance Standard | GB/T 5237.1-2017, ASTM B221, EN 755 |

| Certifications | ISO 9001:2015, IATF 16949:2016, ISO 14001, CE |

| Common Dimensions | 1×3, 2×3, 2×4, 2×6, 3×5, 2×8 (Inches) 20×40, 40×80, 50×100, 100×150 (Metric mm) |

Xingyong Rectangular aluminum tubing Types

Browse our wide selection of aluminum box sections. From standard aluminum 2×4 tubing to custom alloy grades, we have the perfect profile for your project.

aluminum rectangular tubing sizes

2x3 aluminum tubing

1x3 aluminum tube

aluminum 2x4 tubing

1 x 4 aluminum rectangular tubing

1 x 6 aluminum rectangular tubing

2 x 10 aluminum rectangular tubing

2 x 5 aluminum rectangular tubing

2 x 8 aluminum rectangular tubing

Rectangular Aluminum Tubing By Alloy grade

6005 aluminum rectangular tubing

6061 aluminum rectangular tubing

aluminum rectangular tubing 6063

Rectangular Aluminum Tubing Special Features & Shapes

rectangular aluminum tubing rounded corners

aluminum rectangular tubing sharp corners

Heavy duty aluminum rectangular tubing

Rectangular Aluminum Tubing By Surface Finishes

mill finish aluminum rectangular tubing

anodized aluminum rectangular tubing

Powder Coated aluminum rectangular tubing

Why Choose Xingyong Rectangular aluminum tubing

At Xingyong, we combine decades of manufacturing experience with massive power. We control every step from raw material to final aluminum box section to ensure quality and factory-direct pricing.

Premium Raw Materials For Rectangular Aluminum Tubing

We use only premium billets for superior aluminum rectangular hollow section quality. Whether 6061 or 6063, our pure materials ensure excellent durability, welding, and surface finishing results.

High-purity aluminum logs only.

Traceable material reports available.

Superior strength and anodizing results.

One-Stop Customization Service For Rectangular Aluminum Tubing

Need bending rectangular aluminum tubing or custom radius corners? Our CNC workshop offers precision cutting, punching, and custom services to meet your exact aluminum rectangular tubing dimensions.

In-house CNC machining and bending.

Custom lengths and packaging available.

Full OEM logo marking support.

Certified Quality Control For Rectangular Aluminum Tubing

Certified by ISO 9001 and IATF 16949, our lab tests every aluminum rectangle pipe. We use advanced spectrometers to guarantee perfect hardness and surface quality for every batch.

Strict lab testing with spectrometers.

Certified to automotive standards.

100% inspection before shipment.

FAQ of Rectangular aluminum tubing

What is the difference between 6061 and 6063 rectangular tubing?

The main difference lies in their strength and finish. 6061 T6 aluminum rectangular tubing contains magnesium and silicon, making it extremely strong and ideal for structural applications like truck frames and heavy-duty racks. On the other hand, 6063 is softer and offers a smoother surface finish, making it the better choice for architectural trim, window frames, and visible design elements.

What standard aluminum rectangular tubing dimensions are available?

We offer a vast range of standard aluminum rectangular tubing sizes to suit most projects. Common dimensions include 1×2, 1×3, 2×3, 2×4, and larger sections like 2×6. If your project requires specific aluminum rectangular tubing dimensions not listed in our catalog, we can easily create a custom mold to extrude the exact profile you need.

How do I determine the aluminum rectangular tubing weight per foot?

The weight depends on the wall thickness and the overall size of the profile. To get an accurate number, you multiply the cross-sectional area by the density of the aluminum alloy (approx 0.098 lb/in³). We can provide a detailed weight chart for all our products, including aluminum rectangular tubing weight per foot data, to help you estimate shipping and material costs accurately.

Can you provide bending services for rectangular profiles?

Yes, we specialize in deep processing. Bending rectangular aluminum tubing requires precise equipment to prevent the walls from collapsing or buckling. Our facility is equipped to handle various bending radiuses according to your drawings, ensuring the aluminum box section maintains its structural integrity and shape.

Do you supply black aluminum rectangular tubing?

Absolutely. While the standard extrusion comes in a mill finish, we can apply various surface treatments. Black aluminum rectangular tubing is achieved through an anodizing process that not only changes the color but also adds a hard, protective layer against corrosion and wear. We can also provide powder coating in other custom colors.

Related Product Of Rectangular aluminum tubing

If you are sourcing materials for a complete project, you likely need more than just rectangular aluminum tubing. Finding a single supplier for all your metal profiles saves time and logistics costs. At Xingyong, we also manufacture high-quality aluminum square tubing and round aluminum pipes to match your structural requirements. Whether you are building pool cleaning tools or industrial frames, our diverse catalog ensures all your components fit together perfectly. Don’t waste time juggling multiple vendors. Explore our full range of extruded profiles to find the matching aluminum box section solutions you need today.

Telescopic Pool Pole

Solar Panel Cleaning Telescoping Pole

Dusting Extension Pole

Tent Poles Aluminum (Telescoping Type)

Technical Support for Rectangular aluminum tubing

Unsure if 6061 or 6063 is best for your load-bearing structure? Selecting the wrong specs for your rectangular aluminum tubing can lead to costly failures. Visit our technical blog for expert guides on alloy properties, calculating weight per foot, and best practices for bending rectangular aluminum tubing. We share engineering insights to help you optimize your design and manufacturing process. Click here to learn more.

Contact Us

Get factory pricing on rectangular aluminum tubing. Fill the form now for a fast quote on custom orders.

- No. 222, Huaihe East Road, Huaiyin District, Huaian City Jiangsu, China

- info@poolple.com

- (+86)159-9616-7132