LED aluminum profiles are not just housings for LED strips. For OEM brands, project contractors, and large-volume buyers, these factors directly impact heat dissipation, installation efficiency, product lifespan, and after-sales risk.

This article is written from a real aluminum extrusion factory perspective. It explains how LED aluminum profiles are actually made, where designs fail in mass production, how quotations are calculated, and how you can judge whether a price is reasonable—before committing to tooling or bulk orders.

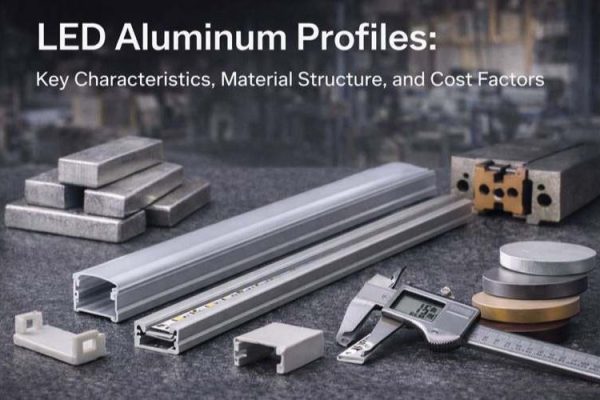

What Are LED Aluminum Profiles?

LED aluminum profiles (also called LED aluminum channels or extrusions) are aluminum housings designed to hold LED strips, diffusers, and accessories. Their main functions are:

- Dissipating heat generated by LEDs

- Protecting LED strips from mechanical damage

- Providing a clean and consistent lighting appearance

In OEM and project-based sourcing, the profile is part of the thermal and structural system, not a decorative accessory.

Key Characteristics That Matter in Real Production

From a factory perspective, not all “good-looking” profiles perform well in mass production.

1. Heat Dissipation (Not Just Thickness)

- Aluminum alloy and wall thickness both affect heat transfer

- Profiles below 1.0 mm wall thickness often show heat buildup in continuous-use applications above 12–14 W/m

- Poor heat dissipation shortens LED lifespan and increases failure rates

2. Structural Stability in Long Lengths

- Long profiles amplify straightness and tolerance issues

- Thin walls deform more easily during extrusion, anodizing, and transport

- For lengths over 2 meters, structural rigidity becomes critical

3. Surface Finish Consistency

- Anodizing quality affects corrosion resistance and appearance

- Inconsistent surface treatment causes color variation between batches

- This is one of the most common causes of OEM complaints

4. Installation Compatibility

- Clip spacing, diffuser fit, and end-cap tolerance matter

- Poor dimensional control leads to loose diffusers or uneven light lines

- These problems usually appear only after bulk installation—not during sampling

Material Composition: What Each Part Really Does

Aluminum Extrusion Body

- Typically made from 6063 aluminum alloy

- Chosen for stable extrusion flow and good thermal conductivity

- Common wall thickness range: 0.8–2.0 mm

- Overly thin designs increase rejection rates in mass production

Diffuser (Cover)

- PC (polycarbonate) or PMMA

- Clear, frosted, or opal finishes

- Opal diffusers improve glare control but reduce light output

End Caps

- Plastic or aluminum

- Protect wiring and improve finished appearance

- Poor-fit end caps often indicate loose extrusion tolerance

Mounting Accessories

- Clips, brackets, or suspension systems

- Directly affects installation speed and labor cost

- Often underestimated during sourcing

Inside a Real LED Aluminum Profile Factory (Xingyong)

This is where most online articles stop—but this is what OEM buyers actually need to know.

Manufacturing Capacity

- Factory established: 2002

- Monthly output: ~3,000 tons of aluminum products

- Extrusion workshop: 14 extrusion lines (350T–2000T)

- Supports multi-cavity and complex profile designs

Surface Treatment Capability

- 2 automatic anodizing lines

- Multiple color options with controlled film thickness

- Typical anodizing thickness:

- 10–15 μm for standard indoor applications

- 20 μm for higher durability requirements

Machining & Secondary Processing

- CNC machining, cutting, drilling, punching, and laser marking

- Suitable for OEM profiles requiring precise accessory fit

Quality Inspection (Not Visual Checks Only)

- Spectrometer for alloy composition

- Profile image measuring instruments

- Hardness testing (Brinell, Webster, Rockwell)

- Coating thickness measurement

- Tensile testing and dimensional inspection

This inspection flow is what keeps samples and bulk orders consistent.

Common Design Mistakes We See from OEM Buyers

These issues appear repeatedly in new projects:

- Designing ultra-thin walls to reduce cost, then facing deformation

- Ignoring anodizing thickness in visible installations

- Assuming samples equal mass production without tolerance discussion

- Mixing diffusers from different suppliers causes a color mismatch

These mistakes increase rework, delays, and warranty risk.

How LED Aluminum Profile Quotations Are Really Calculated

1. Aluminum Material Cost

- Based on the aluminum ingot market price

- Heavier profiles = higher cost per meter

- Alloy stability affects the yield rate

2. Profile Size & Wall Thickness

- Wider and thicker profiles consume more material

- Tight tolerances increase production difficulty

- Complex cross-sections reduce extrusion speed

3. Surface Treatment

- Silver anodizing is the baseline

- Colored anodizing adds cost

- Thicker anodizing films increase processing time and rejection risk

4. Tooling (for Custom Profiles)

- One-time mold cost

- Ownership and modification terms must be confirmed

- Design changes usually require mold adjustment

5. Order Quantity

- Small orders have a higher per-unit cost

- Stable annual volumes allow better pricing

- Tooling cost is amortized over production volume

How to Judge Whether a Quote Is Reasonable

A very low quote often means:

- Reduced wall thickness

- Thinner anodizing film

- Loose dimensional tolerance

- Higher hidden risk in bulk production

A realistic quote balances:

- Structural performance

- Surface consistency

- Production yield

- Long-term supply stability

For OEM buyers, total cost over time matters more than initial unit price.

Faster, Clearer Quotation: What to Prepare

To receive an accurate quote, provide:

- Profile drawing or reference sample

- Required length and wall thickness

- Surface finish and color

- Diffuser type

- Estimated annual quantity

Clear specifications reduce misunderstandings and shorten lead time.

Reduce Risk Before Mass Production

Before committing to tooling or large orders, validate your design under real production conditions.

Recommended next steps:

- Request a physical sample

- Review wall thickness and anodizing specifications

- Confirm extrusion feasibility and tolerance limits

- Align on pricing logic before volume commitment

A controlled start saves time, cost, and brand reputation in the long run.