If you work with outdoor or water-exposed products, this question always comes up: Does aluminum rust?

The short answer is no — aluminum does not rust like steel. But the longer, more useful answer matters much more when you are choosing materials for real products, real customers, and long-term use.

This guide explains what actually happens to aluminum, how it behaves in water and outdoor environments, and what buyers should check before sourcing aluminum parts at scale.

What “Rust” Really Means — and Why Aluminum Is Different

Rust is a very specific type of corrosion. It only happens to metals that contain iron.

- Rust forms when iron reacts with oxygen and moisture

- It creates flaky, reddish-brown material

- Over time, rust eats into the metal and weakens it

Aluminum contains no iron, so it cannot rust in the technical sense.

That difference alone explains why aluminum is widely used for outdoor and water-related products.

Does Aluminum Corrode?

Yes — but not in the same way as steel.

When aluminum is exposed to air, it reacts with oxygen almost instantly and forms a thin oxide layer on its surface.

- This layer is invisible

- It sticks tightly to the aluminum

- It blocks further reaction with air or water

In simple terms, aluminum protects itself.

Instead of spreading damage like rust, aluminum’s oxidation stops at the surface.

Does Aluminum Rust in Water?

Aluminum does not rust in water, but the environment still matters.

Fresh water

- Aluminum performs very well

- Oxide layer stays stable

- No structural damage under normal conditions

Humid environments

- Oxide layer remains intact

- Surface appearance may dull slightly over time

- Strength is not affected

Long-term exposure

- Aluminum keeps its shape and strength

- No flaking, no deep penetration like rusted steel

This is why aluminum is commonly used in pool equipment, outdoor frames, and telescopic poles.

What About Pool Water and Chlorine?

Pool water introduces chemicals, mainly chlorine.

This is where material choice and surface treatment become important.

- Bare aluminum already performs well in pool environments

- Anodized aluminum performs even better

- Proper surface treatment reduces discoloration and surface wear

For products like pool cleaning poles that are constantly wet, aluminum remains a reliable option when manufactured correctly.

Aluminum Oxidation vs Rust — A Practical Comparison

| Feature | Aluminum | Steel |

|---|---|---|

| Rust formation | No | Yes |

| Surface reaction | Thin oxide layer | Expanding rust |

| Structural impact | Minimal | Severe over time |

| Maintenance | Low | High |

| Outdoor suitability | Excellent | Limited without coating |

This difference explains why aluminum is preferred in applications where maintenance access is limited or where appearance matters.

How Surface Treatment Changes Aluminum’s Performance

Not all aluminum performs the same. Surface treatment plays a big role.

Raw aluminum

- Naturally corrosion resistant

- Suitable for many indoor and mild outdoor uses

Anodized aluminum

- Thicker, controlled oxide layer

- Better resistance to chemicals and abrasion

- More consistent appearance over time

For OEM buyers, anodizing quality and consistency matter just as much as the base material.

Does Anodized Aluminum Rust?

No. Anodized aluminum does not rust.

In fact, anodizing strengthens aluminum’s natural protection:

- Improves corrosion resistance

- Reduces surface wear

- Enhances color stability

That’s why anodized aluminum is widely used for premium pool poles, outdoor tools, and branded products.

Aluminum vs Steel for Outdoor Products

Many buyers compare aluminum with steel before making a decision.

Aluminum advantages

- Will not rust

- Lightweight

- Easy to handle and ship

- Low maintenance

Steel limitations

- Rust risk without coatings

- Heavier

- Higher long-term maintenance cost

For telescopic products or tools used daily, aluminum usually offers better lifetime value.

Real-World Applications Where Rust Resistance Matters

Aluminum’s corrosion resistance is not theoretical. It shows up in daily use.

Common examples include:

- Pool cleaning poles

- Pool cover reel systems

- Outdoor telescopic tools

- Structural aluminum tubing

In these applications, aluminum maintains function and appearance even after repeated exposure to water and outdoor conditions.

Common Misunderstandings About Aluminum and Rust

Let’s clear up a few frequent myths.

“Aluminum is completely immune to corrosion.”

Not true. It can corrode under extreme conditions, but very slowly.“Oxidation means failure.”

Aluminum oxidation is protective, not destructive.“All aluminum performs the same.”

Alloy choice, processing, and surface treatment make a big difference.

Understanding these points helps buyers avoid poor sourcing decisions.

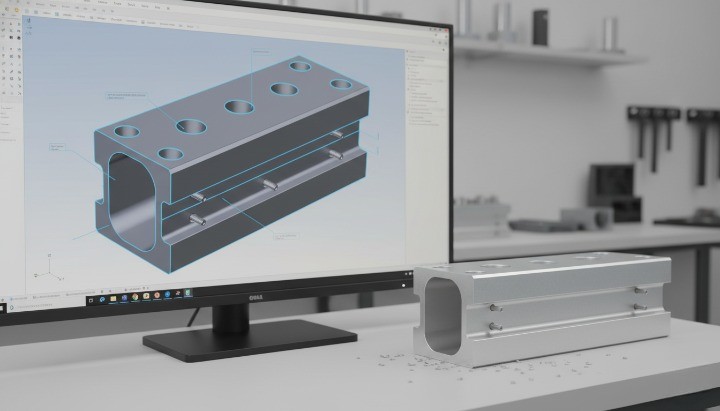

What OEM Buyers Should Check When Sourcing Aluminum Products

If you are sourcing aluminum parts or finished products, rust resistance depends on more than the material name alone.

Key points to check:

- Aluminum alloy selection

- Surface treatment process

- Anodizing thickness and uniformity

- Quality control during production

- Inspection and testing standards

Experienced manufacturers control these factors in-house to ensure consistent performance across batches.

FAQ: Does Aluminum Rust in Specific Conditions?

Does aluminum rust outdoors?

No. It forms a protective oxide layer and remains structurally stable.

Does aluminum rust in saltwater?

It does not rust, but marine environments require proper alloy and surface treatment.

Will aluminum rust during shipping or storage?

No. Aluminum is well-suited for international transport and long storage periods.

Does painted aluminum rust if scratched?

Scratches may expose raw aluminum, but it still will not rust like steel.

Final Thoughts: Is Aluminum the Right Choice?

Aluminum does not rust, and that simple fact explains its popularity in outdoor and water-related products. More importantly, aluminum offers predictable performance, low maintenance, and long service life when sourced from capable manufacturers.

For brands, OEM buyers, and distributors, the real question is not whether aluminum rusts — it’s whether the aluminum product is designed and produced correctly for its environment.

If you are evaluating aluminum components for pool or outdoor use, focus on material quality, surface treatment, and manufacturing consistency. Those details determine how well aluminum performs over the years of real-world use.