A Practical Guide for Buyers, Engineers, and OEM Brands

Yes — aluminum can be powder coated, and it’s one of the most common finishing methods used for aluminum products today. If you source aluminum parts for outdoor use, retail products, or branded consumer goods, powder coating is often the finish that balances appearance, durability, and cost.

This guide explains how powder coating works on aluminum, when it makes sense, and what you should confirm with your supplier before placing an order.

Short Answer First — Yes, Aluminum Can Be Powder Coated

Aluminum accepts powder coating very well when the surface is prepared correctly. The coating bonds to the metal through electrostatic attraction and heat curing, creating a hard, even finish.

However, results depend on:

- Proper surface pretreatment

- Correct alloy selection

- Stable curing temperature control

When these steps are skipped, issues like peeling or bubbling can occur.

Why Powder Coating Works Well on Aluminum

Aluminum behaves differently from steel, and that matters during finishing.

Key reasons powder coating is suitable:

- Aluminum does not rust, making it ideal for outdoor powder-coated products

- It tolerates curing temperatures without warping

- Powder coating creates a thicker, more uniform layer than liquid paint

For buyers, this means fewer finish complaints and better consistency across batches.

Aluminum Powder Coating Process (Factory-Level Breakdown)

A reliable factory follows a controlled, repeatable process. Below is what you should expect.

1. Cleaning and Degreasing

- Removes oil, dust, and machining residue

- Prevents adhesion failure later

2. Surface Pretreatment

- Converts the aluminum surface for better coating adhesion

- Chromate or chrome-free systems are commonly used

- This step directly affects outdoor durability

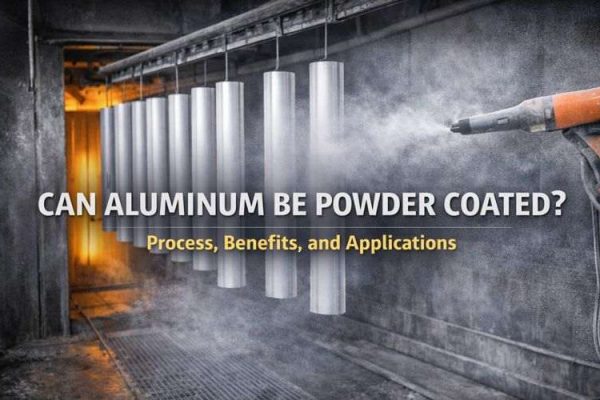

3. Electrostatic Powder Application

- Powder is sprayed evenly using electrostatic guns

- Ensures consistent thickness on profiles and tubes

4. Oven Curing

- Parts are heated until the powder melts and flows

- Temperature and time control are critical for color stability

Common Aluminum Alloys Used for Powder Coating

Not all aluminum alloys finish the same.

-

- Smooth surface

- Excellent for extruded profiles and tubes

- Preferred for visible consumer products

-

- Higher strength

- More machining marks

- Requires extra surface prep for cosmetic finishes

For telescopic poles and pool equipment, 6063 is often the better choice when appearance matters.

Powder Coating vs Anodizing Aluminum

Both finishes are widely used, but they serve different needs.

- Wider color range

- Thicker protective layer

- Easier color matching for branding

- Better for retail-facing products

- Metallic appearance

- Thinner coating

- Limited color options

- Better for precision parts

If your product is customer-facing or color-critical, powder coating is usually the safer option.

Typical Problems When Powder Coating Aluminum (And How to Avoid Them)

Most coating failures come from shortcuts, not the material itself.

Common issues:

- Poor adhesion → caused by weak pretreatment

- Bubbles or pinholes → moisture trapped in the metal

- Color inconsistency → unstable curing or powder batch variation

Experienced factories reduce these risks with:

- Controlled pretreatment lines

- Coating thickness checks

- Batch-level color inspection

Real-World Applications of Powder Coated Aluminum

Powder coated aluminum is widely used in:

- Aluminum telescopic poles

- Pool cleaning and maintenance equipment

- Outdoor consumer products

- Retail-ready items for big-box stores

For pool poles in particular, powder coating improves grip feel, visual appeal, and shelf presentation.

What Buyers Should Confirm Before Ordering Powder Coated Aluminum

Before you place an order, confirm these points with your supplier:

- Pretreatment standard used

- Coating thickness range

- Color matching tolerance

- Gloss level consistency

- Inspection and testing methods

- Re-coating options for rejects

Clear answers here prevent quality disputes later.

FAQ

Does powder coated aluminum rust?

No. Aluminum does not rust. The coating mainly protects against corrosion, fading, and surface wear.

How long does powder coating last outdoors?

With proper pretreatment, powder coated aluminum can last many years outdoors, even in humid or poolside environments.

Can aluminum be powder coated again?

Yes. Old coatings can be stripped and re-applied if needed.

Why Buyers Work With Xingyong

Xingyong has been manufacturing aluminum products since 2002, with in-house extrusion, surface finishing, machining, and inspection.

What this means for you:

- Monthly capacity of 3,000 tons

- Multiple automated surface treatment lines

- Full inspection using spectrometers, hardness testers, and coating thickness gauges

- Experience supplying OEM and retail-focused pool equipment

You deal with one factory, not a chain of subcontractors.

Ready to Move Forward?

- Request a powder-coated aluminum sample

- Download our surface finish specification

- Talk directly with our export and engineering team

Contact Xingyong today to discuss your aluminum powder coating requirements.