Annealing aluminum is not a lab concept—it’s a production decision that directly affects forming success, assembly efficiency, and defect rates.

If your aluminum parts are bent, expanded, drawn, or used in telescopic systems, annealing often determines whether production runs smoothly or stalls with cracks and rework.

This guide explains what annealing aluminum is, how it works in real factories, and how you should specify it when sourcing aluminum parts.

What Is Annealing Aluminum?

Annealing aluminum is a controlled heat process used to soften aluminum by relieving internal stress created during extrusion, drawing, or forming.

In plain language:

- Working with aluminum makes it harder and less forgiving.

- Annealing resets the metal’s internal structure.

- The result is aluminum that bends, expands, and slides more easily.

Nothing changes visually. The difference shows up during forming and assembly, where cracks either appear or don’t.

Why Annealing Aluminum Matters in Real Manufacturing

Most aluminum parts are not finished after extrusion. They are:

- Bent into shape

- Expanded or flared

- Drawn into thinner sections

- Assembled into telescopic systems

Each step adds stress. Without annealing, that stress accumulates.

In production, annealing helps you:

- Reduce cracking during bending and expansion

- Improve consistency across long tubes

- Lower assembly force and friction

- Stabilize dimensions in secondary processing

For products like telescopic poles or thin-wall tubes, annealing is often not optional—it’s preventive.

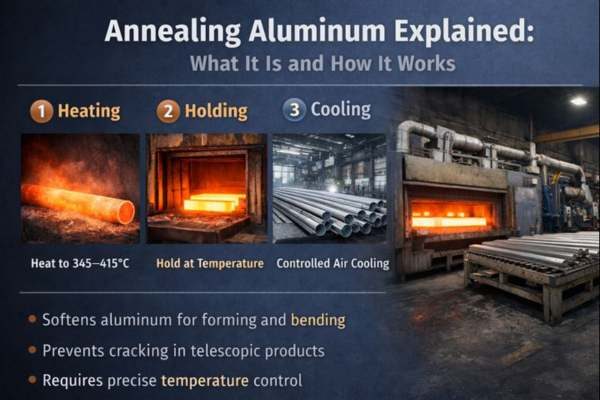

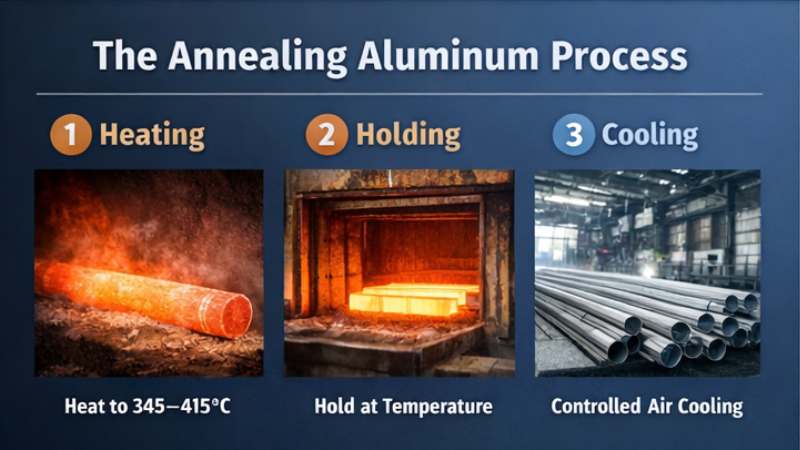

How the Aluminum Annealing Process Works (Step by Step)

Annealing aluminum follows three controlled stages. Problems usually occur when one of them is rushed or uneven.

1. Heating

Aluminum is heated to a defined temperature range based on alloy type.

Uniform heating is critical, especially for long tubes where end-to-end variation is common.

2. Holding

The aluminum stays at a temperature long enough for internal stresses to release.

Insufficient holding leaves the metal partially hard; excessive holding can weaken the grain structure.

3. Cooling

Most aluminum annealing uses natural or controlled air cooling.

Unlike steel, rapid quenching is not required for annealing aluminum.

Aluminum Annealing Temperature by Alloy Series

Different alloys respond differently to heat. Treating them the same is a common production mistake.

| Alloy Series | Typical Annealing Range | Practical Notes |

|---|---|---|

| 3xxx | 345–415 °C | Stable, forgiving, widely used in tubing |

| 5xxx | 345–415 °C | Magnesium content requires careful control |

| 6xxx | 350–410 °C | Common for telescopic poles and structural tubes |

Real-world issue:

For 6xxx series tubes used in telescopic systems, under-annealing often shows up as cracking during expansion or rough sliding during assembly.

How Annealing Changes Aluminum Properties (What You’ll Actually Notice)

Annealing changes how aluminum behaves—not how it looks.

After annealing:

- Hardness decreases

- Ductility increases

- Forming force drops

- Sliding surfaces move more smoothly

The trade-off is strength. That’s why many products are annealed before forming, then heat-treated later if higher strength is needed.

Annealing vs Heat Treatment: A Clear Difference for Buyers

These two processes are often confused—but they do opposite things.

- Annealing: softens aluminum to make forming possible

- Heat treatment: strengthens aluminum after forming

If your aluminum cracks during bending, annealing is the solution.

If your aluminum bends too easily in use, heat treatment is the solution.

They solve different problems.

Factory Example: Annealing Aluminum for Telescopic Pool Poles

Telescopic pool poles place high demands on aluminum tubes:

- Thin walls

- Long lengths

- Repeated sliding during use

Before controlled annealing, common production issues include:

- Cracking during tube expansion

- Uneven sliding feel between inner and outer tubes

- High rejection rates at assembly

After introducing a controlled annealing step:

- Tube expansion became more stable

- Sliding friction decreased

- Assembly defects were significantly reduced

For telescopic aluminum products, annealing is often the difference between smooth assembly and constant adjustment.

Common Aluminum Annealing Mistakes (Seen in Production)

Even experienced suppliers can get annealing wrong.

Typical problems include:

- Over-annealing, which causes excessive softness and poor wear resistance

- Uneven heating, especially in long aluminum profiles

- Skipping verification, assuming annealing worked without testing

Reliable manufacturers verify annealing results using:

- Hardness testing

- Dimensional checks

- Forming or expansion trials

This step prevents defects from showing up later—when fixes are expensive.

Do You Need Annealed Aluminum for Your Product?

You should specify annealed aluminum if your product involves:

- Telescopic movement

- Tube expansion or flaring

- Tight bending radii

- Secondary forming after extrusion

If your part is only cut to length with no further forming, annealing may not be necessary.

When in doubt, discuss your entire processing sequence, not just the final product.

What to Confirm with Your Supplier Before Ordering Annealed Aluminum

This is where many sourcing problems begin—not with quality, but with unclear specifications.

Before placing an order, confirm:

- Alloy series and temper

- Tube length and wall thickness

- Post-annealing operations (bending, expansion, sliding)

- How annealing quality is verified

- Whether annealing is full-length or partial

Clear communication here prevents cracks, delays, and rework later.

FAQ: Annealing Aluminum

Can aluminum be annealed more than once?

Yes. Aluminum can be re-annealed if additional forming is required.

Does annealed aluminum stay soft permanently?

It stays soft unless further worked or heat-treated.

Is annealing required for all aluminum tubes?

No. It depends on forming and assembly requirements.

How can buyers verify annealing quality?

By requesting hardness data, forming samples, or trial assemblies.

Reduce Risk Before Mass Production

Annealing aluminum is simple in theory—but unforgiving in practice.

If your aluminum parts require bending, expansion, or telescopic movement, confirming annealing details before mass production helps avoid costly rework and delays.

Request a sample or discuss your aluminum application with an experienced production team before placing bulk orders.