If you are sourcing extruded aluminum parts, the difference between 6061 and 6063 is not a textbook question.

It is a cost, quality, and risk decision.

We’ve seen OEM projects where the wrong alloy choice led to:

- unstable extrusion dimensions,

- uneven anodized color,

- higher scrap rates,

- and retail rejections after mass production.

This guide explains how experienced OEM suppliers choose between 6061 and 6063, using real production logic—not just material data sheets.

Why This Choice Matters More Than Most Buyers Expect

Many buyers start with one simple idea:

“6061 is stronger, so it must be better.”

In extrusion-based products, that assumption often backfires.

For products like aluminum telescopic poles, pool cleaning poles, and long thin tubes, what really matters is:

- consistency across thousands of pieces,

- surface quality after anodizing,

- and stable production over time.

In several OEM projects we’ve supported, switching from 6061 to 6063 reduced rework and cosmetic rejection by more than 10–15% at scale.

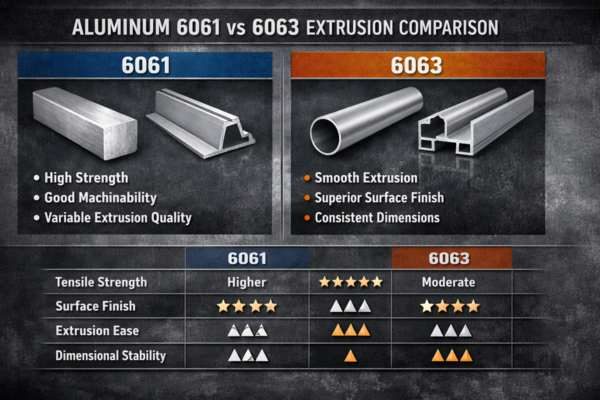

6061 vs 6063: The Short, Honest Explanation

Both alloys belong to the 6000 series and contain magnesium and silicon.

That’s where the similarity ends.

- 6061 is optimized for strength and machining

- 6063 is optimized for extrusion quality and surface finish

Neither is “better” in general.

Each is better for different manufacturing realities.

Strength Numbers vs Real-World Performance

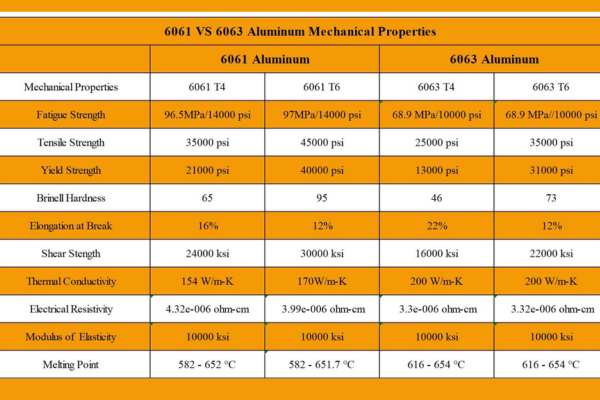

Typical T6 temper values:

- 6061-T6

- Tensile strength: ~290 MPa

- Yield strength: ~240 MPa

- 6063-T6

- Tensile strength: ~240 MPa

- Yield strength: ~215 MPa

On paper, 6061 looks superior.

In practice, for thin-wall extruded tubes, strength alone does not determine bending resistance or durability.

What matters more is:

- wall thickness uniformity,

- straightness,

- and dimensional stability.

Inconsistent walls cancel out theoretical strength advantages very quickly.

Extrusion Behavior: Where Most Problems Start

This is the point most online articles skip.

6063 extrudes more smoothly.

That means:

- lower extrusion pressure,

- better metal flow,

- and a cleaner profile definition.

For OEM production, this results in:

- tighter tolerances over long runs,

- less die wear,

- fewer dimensional rejects.

6061, by contrast:

- is more sensitive to temperature variation,

- requires tighter process control,

- and shows greater batch-to-batch variation in long profiles.

If your product relies on a multi-section fit, this difference becomes apparent immediately.

Anodizing & Surface Finish: Where Buyers Feel the Pain

For consumer-facing products, surface quality is not optional.

In real production:

- 6063 anodizes more evenly

- Color consistency is easier to control

- Surface streaking is less common

With 6061, suppliers often face:

- visible color shifts between batches,

- more polishing before anodizing,

- Higher cosmetic rejection rates.

For OEM buyers supplying retailers or branded channels, this difference directly affects acceptance rates and customer complaints.

Telescopic Poles: Why 6063 Is Used in Most Designs

Telescopic poles are unforgiving products.

They require:

- thin walls,

- smooth sliding between sections,

- straightness over long lengths,

- and a consistent outer diameter.

6063 allows:

- thinner, more stable walls,

- smoother section fit,

- better long-term consistency.

This is why most aluminum telescopic pool poles use 6063, even when buyers initially request 6061.

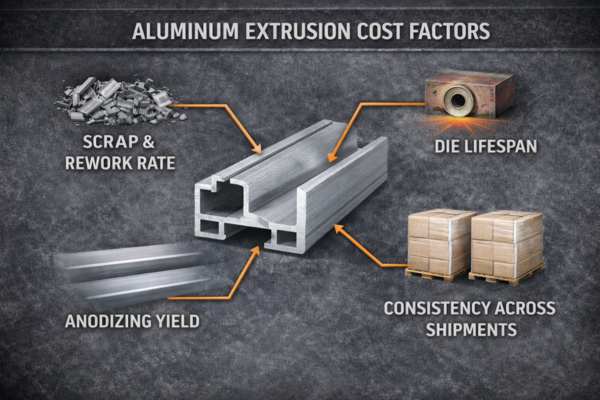

The Real Cost Difference (Not the Invoice Price)

Raw material price differences between 6061 and 6063 are usually small.

The real cost difference appears after production starts.

Key cost drivers:

- scrap and rework rate,

- the lifespan,

- anodizing yield,

- consistency across shipments.

In high-volume OEM projects, 6063 often delivers a lower total landed cost, even when material pricing is similar.

When 6061 Is the Right Choice

6061 should not be dismissed. It excels in the right context.

Choose 6061 when:

- parts require heavy CNC machining,

- structural strength is critical,

- appearance is secondary,

- Volumes are moderate.

Typical uses include:

- machined brackets,

- industrial frames,

- load-bearing components.

When 6063 Is the Smarter OEM Decision

6063 is usually the better choice when:

- extrusion quality matters more than peak strength,

- surface finish affects product value,

- Production volume is high,

- Consistency matters across multiple shipments.

Common applications:

- aluminum telescopic poles,

- pool cleaning poles,

- architectural profiles,

- display systems.

Common Buyer Mistakes That Lead to Problems

After supporting OEM aluminum projects for years, the same issues appear again and again:

- choosing 6061 “just to be safe.”

- ignoring anodizing behavior during design

- over-specifying strength without checking wall tolerance

- comparing only price per ton, not total cost

These mistakes usually show up after mass production begins.

How Xingyong Approaches Alloy Selection

At Xingyong, alloy selection is based on production reality, not assumptions.

What we bring to your project:

- Over 20 years of aluminum extrusion experience

- 14 extrusion lines from 350T to 2000T

- In-house anodizing and surface treatment

- Full inspection with spectrometers and mechanical testing

- Recommendations based on actual product use, not theory

Our goal is simple:

help you choose an alloy that works reliably at scale.

Final Decision Guide (Plain and Direct)

- Choose 6061 if strength and machining are your top priorities.

- Choose 6063 if extrusion quality, appearance, and consistency matter more.

For most extruded consumer products, especially telescopic designs, 6063 is the safer OEM choice.

Ready to Validate Your Choice?

If you are unsure which alloy your current design truly needs, it’s better to verify now than fix problems after production starts.