Premier Aluminum Square Tubing Manufacturer in China

Since 2002, Xingyong has delivered precision solutions for global brands. We combine high-capacity extrusion with advanced fabrication to meet your wholesale and customized needs for aluminum square tubing.

High-grade raw ingots guarantee stable chemical composition for structural durability.

Custom 6061 and 6063 aluminum square tubing extruded to your exact specifications.

- ISO 9001 certified factory with 14 presses ensuring consistent, on-time delivery.

Complete anodizing and CNC services for ready-to-assemble commercial products.

What is Aluminum Square Tubing

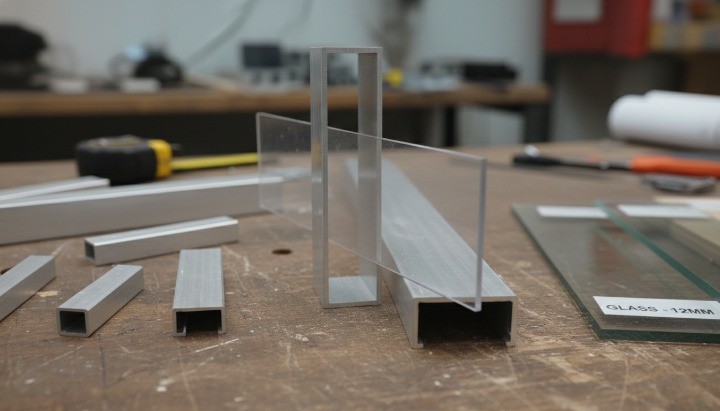

Aluminum square tubing is a hollow, box-shaped metal bar known for being very light yet strong. It is usually made from aluminum alloys like 6061 or 6063, which helps it resist rust and weather damage. This makes it a great choice for both indoor and outdoor projects. Builders and factories use it because it is easy to cut, weld, and shape. You will often see this tubing used to make sturdy frames, railings, and support structures that last a long time.

Aluminum Square Tubing Specifications

| Attribute | Specification Details |

|---|---|

| Material Grade (Alloy) | 6061 (Al-Mg-Si), 6063, 6005, 6082 |

| Temper | T3, T4, T5, T6 |

| Standard Sizes (Imperial) | 0.5″ x 0.5″, 1″ x 1″, 1.5″ x 1.5″, 2″ x 2″, 3″ x 3″, 4″ x 4″, up to 8″ |

| Standard Sizes (Metric) | 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm, 80mm, 100mm, up to 200mm |

| Wall Thickness | Thin Wall: 0.8mm – 1.5mm Standard: 1.5mm – 3.0mm Heavy Duty: 3.0mm – 10.0mm |

| Length | Standard: 2ft, 4ft, 6ft, 8ft, 10ft, 12ft, 21ft, 24ft (Container loading size) Custom Cut: Precision cutting to any length |

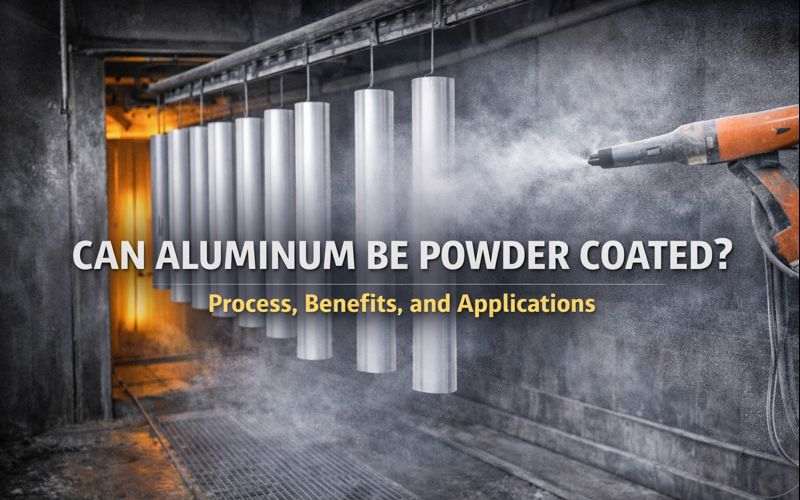

| Surface Treatment | Anodized: Clear, Black, Gold, Bronze (Film thickness: 8-25μm) Powder Coated: Any RAL Color (60-120μm) Mill Finish: Raw aluminum finish |

| Corner Type | Sharp Corner (90° precise angle) Radius Corner (Rounded edges for telescoping) |

| Certifications | ISO 9001:2015, ISO 14001, IATF 16949, SGS, RoHS |

Mechanical Properties (6061 vs. 6063)

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Best For |

|---|---|---|---|

| 6063-T5 | ≥ 160 | ≥ 110 | Architectural: Window frames, furniture, trim. Excellent surface finish. |

| 6061-T6 | ≥ 265 | ≥ 245 | Structural: Heavy-duty frames, truck racks, machinery. High strength. |

Xingyong Aluminum Square Tubing Categories

You need a supplier who can adapt to your specific market demands. At Xingyong, we offer a diverse range of aluminum square tubing designed to suit various industries, from architectural design to heavy-duty machinery. Our comprehensive inventory and custom capabilities ensure you get the right alloy, finish, and dimensions for your application. Browse our categories below to find the perfect match for your business.

Aluminum Square Tubing By Alloy Type

6061 Aluminum Square Tubing

6063 Aluminum Square Tubing

6005 Aluminum Square Tubing

Aluminum Square Tubing By Surface Finish

Anodized Aluminum Square Tubing

Powder Coated Aluminum Square Tubing

Mill Finish Aluminum Square Tubing

Polished Aluminum Square Tubing

Aluminum Square Tubing By Structure and Function

Telescoping Aluminum Square Tubing

Radius Corner Aluminum Square Tubing

Sharp Corner Aluminum Square Tubing

Thin Wall Aluminum Square Tubing

Heavy Duty Aluminum Square Tubing

Aluminum Square Tubing By Size Dimensions

1x1 Aluminum Square Tubing

2x2 Aluminum Square Tubing

3x3 Aluminum Square Tubing

4x4 Aluminum Square Tubing

Aluminum Square Tubing By Color Options

Black Aluminum Square Tubing

White Aluminum Square Tubing

Why Choose Xingyong Aluminum Square Tubing

When you partner with Xingyong for your aluminum square tubing supply, you are choosing a manufacturer that prioritizes your business growth. We combine premium raw aluminum ingots with advanced extrusion technology to deliver durable, high-precision profiles that fit your telescoping poles and structural projects perfectly. Our integrated factory controls every step, ensuring you get consistent quality and on-time delivery without the hassle of dealing with multiple middlemen. Contact our team today to start your custom order.

Premium Raw Material Control For Aluminum Square Tubing

We insist on using high-quality aluminum ingots to manufacture our 6061 and 6063 aluminum square tubing, rather than relying on low-grade recycled scrap. This commitment ensures that the internal structure of the metal is dense and uniform, providing better strength and a flawless surface for anodizing.

Pure Alloy Composition: Strict adherence to international alloy standards.

Better Finish: Minimizes surface defects like streaks or spots.

Longer Lifespan: Enhanced resistance to environmental corrosion.

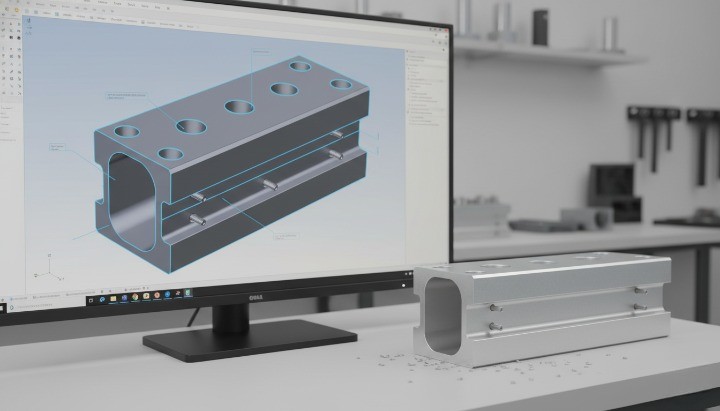

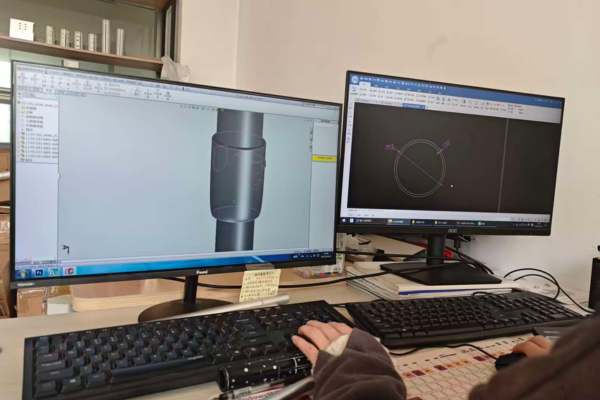

Comprehensive Customization and Fabrication For Aluminum Square Tubing

From precision cutting to complex CNC machining, we deliver custom aluminum square tubing ready for final assembly. We support your brand identity by offering laser marking, custom hole punching, and specialized packaging solutions based on your drawings or samples.

One-Stop Service: Drilling, punching, milling, and bending in-house.

Brand Support: Custom logos and retail-ready packaging available.

Design Flexibility: We accept drawings, samples, or raw material for processing.

Certified Quality You Can Trust in Every Aluminum Square Tubing

Our aluminum square tubing undergoes rigorous testing in our advanced detection center, equipped with Oxford spectrometers and cross-section scanners. We hold certifications like ISO 9001:2015 and IATF 16949:2016, giving you the documentation and peace of mind required for global markets.

Rigorous Testing: Chemical analysis, hardness testing, and film thickness checks.

Global Standards: Compliant with BSCI and Energy Management systems.

Traceability: Every batch is tracked and documented.

FAQ of Aluminum Square Tubing

How to bend aluminum square tubing?

Bending aluminum square tubing requires the right tools to prevent kinking or collapsing the walls. A draw bender with an internal mandrel is the best method, as it supports the tube from the inside. If you are working with 6061-T6 alloy, it is quite stiff and may crack, so annealing it first or choosing a softer temper like T4 is recommended. For complex shapes, our factory offers professional bending services to ensure precise curves.

How to connect aluminum square tubing without welding?

You can connect aluminum square tubing easily using mechanical fasteners. Nylon or plastic tubing connectors are popular for light frames, creating clean 90-degree joints. For structural strength, bolted brackets or gusset plates are ideal. If you are building a telescoping system, we recommend using flip-locks or cam-locks, which allow the tubes to slide and lock securely without permanent fixation.

How much weight can 1 inch aluminum square tubing hold?

The weight capacity depends on the alloy, wall thickness, and the length of the span. A standard 1×1 aluminum square tubing made of 6061-T6 alloy is very strong for its size. However, as the length increases, the tube becomes more likely to bend under load. For safety in critical projects, we recommend consulting a structural engineer or asking our technical team for a load chart based on your specific dimensions.

How to cut aluminum square tubing?

The best way to cut aluminum square tubing is using a miter saw equipped with a non-ferrous carbide-tipped blade. Unlike cutting steel, you should use a lubricant like cutting wax or WD-40 to prevent the soft aluminum from clogging the blade teeth. This ensures a clean, burr-free cut that is ready for assembly or welding.

How to straighten aluminum square tubing?

If a tube gets bent during shipping or use, straightening it perfectly by hand is difficult. Minor bends can sometimes be fixed by placing the tube on a flat surface and applying pressure with a clamp or hydraulic press. However, applying heat can weaken the heat-treated temper (like T6). We ensure our factory-direct aluminum square tubing is straightened on the extrusion line to meet strict straightness tolerances before it reaches you.

How to weld aluminum square tubing?

Welding aluminum square tubing is typically done using TIG (GTAW) or MIG (GMAW) welding. The most important step is preparation; you must clean the surface thoroughly to remove the natural oxide layer before welding. While 6061 alloy welds well, the heat can reduce the strength of the metal near the joint. For mass production, we offer pre-fabricated welding services to save you time and labor.

What is the difference between 6061 and 6063 aluminum square tubing?

The main difference lies in their application. 6061 aluminum square tubing contains magnesium and silicon, offering higher structural strength for heavy-duty frames. 6063 aluminum square tubing, often called “architectural aluminum,” has a smoother surface finish and is easier to extrude into complex shapes, making it ideal for visible trim and furniture.

Related Product Of aluminum square tubing

Optimizing your supply chain means sourcing all your related components from one trusted manufacturer. If you are purchasing aluminum square tubing for pool maintenance tools, check out our finished Aluminum Pool Cleaning Poles and Pool Cover Reels. We also manufacture Aluminum Round Tubing and custom industrial profiles that complement your square tube structures. Explore our full catalog to bundle your orders and save on shipping costs.

Dusting Extension Pole

Brush Extension Pole

Squeegee Extension Pole

Telescoping Pole Saw

Technical Support for aluminum square tubing

We are here to help you solve technical challenges. Whether you need an alloy selection chart to choose between 6061 and 6063, or a chemical composition report for your aluminum square tubing, our resource center has you covered. We provide detailed CAD drawings for our telescoping aluminum square tubing systems and guidance on surface maintenance for anodized products. Visit our Blog or download our technical datasheets to ensure you are specifying the right product for your application.

Contact Us

Ready to start your order? Fill out the form to get a competitive quote on wholesale aluminum square tubing. Whether you need standard sizes or custom OEM fabrication, our team is ready to support your business.

- No. 222, Huaihe East Road, Huaiyin District, Huaian City Jiangsu, China

- info@poolple.com

- (+86)159-9616-7132