Aluminum does not have one fixed color.

What you see depends on the alloy, surface finish, and how the product is made. For OEM brands and retail buyers, understanding this helps reduce color complaints, returns, and rework.

This guide explains aluminum’s natural color, how finishes change its appearance, and how you should specify color in bulk orders.

The Natural Color of Aluminum

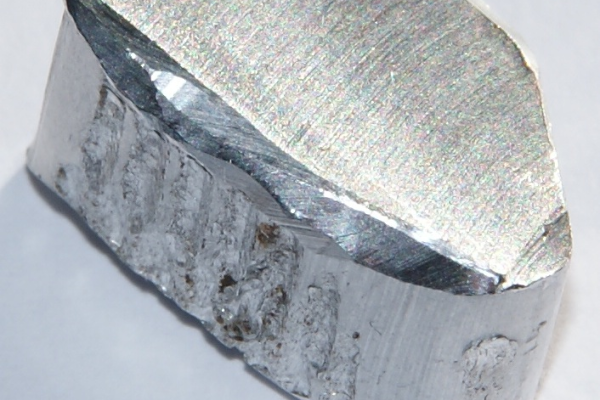

In its untreated state, aluminum appears light silver-gray.

- Freshly cut aluminum looks bright and metallic

- A thin natural oxide layer forms instantly in air

- This oxide layer protects aluminum but slightly softens shine

Different alloys reflect light differently. For example, 6063 aluminum usually looks smoother and brighter than 6061, even before surface treatment.

For buyers, this means: “natural aluminum color” is a visual description, not a controlled standard.

Is Aluminum Silver or Gray?

Both descriptions are correct—but incomplete.

- Silver describes reflectivity

- Gray describes base tone

- Lighting and surface texture affect what your eye sees

In procurement terms, “silver” is not a specification. Two suppliers can ship “silver aluminum” that looks different side by side.

If color matters for your product or brand, you need more detail than a single word.

Mill Finish Aluminum: Color vs Reality

Mill finish aluminum is aluminum as it leaves the extrusion process, with no added surface treatment.

Typical mill finish appearance:

- Light silver-gray tone

- Fine extrusion lines

- Slight brightness variation along length

For OEM and retail products, mill finish has risks:

- Color consistency varies by batch

- Surface marks are visible under store lighting

- Retail customers often see it as “unfinished”

Mill finish works best for internal parts or cost-sensitive projects—not for consumer-facing pool poles.

How Surface Finishes Change Aluminum’s Color

Surface treatment defines aluminum’s final appearance more than the metal itself.

Anodized Aluminum

Anodizing thickens the natural oxide layer.

For outdoor products like pool poles, anodizing improves color stability under sun and chemicals.

Powder Coated or Painted Aluminum

This adds a colored coating on top of the metal.

- Widest color choice

- Strong visual consistency

- Best option for brand color matching

Trade-off: higher cost and higher MOQ.

Why Color Consistency Matters in Retail and OEM Orders

Color variation is one of the top causes of retail rejection.

Common causes include:

- Different aluminum batches

- Different anodizing tanks or times

- Alloy variation across suppliers

Professional buyers avoid problems by:

- Approving physical samples

- Defining finish type clearly

- Setting acceptable color tolerance (ΔE)

At Xingyong, color consistency is checked using controlled lighting and measurement tools before shipment.

Real Example: Aluminum Pool Poles for Outdoor Use

Pool cleaning poles are exposed to:

- UV sunlight

- Chlorinated water

- Constant handling

Without proper surface treatment:

- Color dulls over time

- Surface turns chalky

- Visual mismatch appears between sections

High-quality anodizing reduces these issues and keeps the pole looking consistent on retail shelves.

How to Specify Aluminum Color in OEM Orders

Avoid vague terms like “silver aluminum.”

Use one of these instead:

- “6063 aluminum, clear anodized, matte finish.”

- “Anodized aluminum, champagne color, sample approved”

- “Powder coated aluminum, RAL 9006”

Always confirm with:

- Pre-production samples

- Approved color references

- Written finish description in PO

This saves time, cost, and disputes later.

FAQ: Common Buyer Questions About Aluminum Color

Is aluminum always silver?

No. Its appearance depends on surface treatment.

Does aluminum change color over time?

Untreated aluminum dulls. Anodized aluminum stays stable longer.

Why do two aluminum poles look different?

Different batches, alloys, or finishing processes.

Is anodized aluminum darker than raw aluminum?

Usually yes, but thickness and finish style matter.

Why Work with an Experienced Aluminum Manufacturer

With high-volume retail and OEM projects, color control is not optional.

Xingyong has produced aluminum products since 2002, with in-house extrusion, anodizing, machining, and inspection. This allows tighter control over appearance, consistency, and delivery.

👉 Learn more about our aluminum pool pole manufacturing

Call to Action

- Request a color sample

- Discuss your OEM finish requirements

- Get technical guidance before mass production

Contact our export team to avoid costly color issues in your next order.