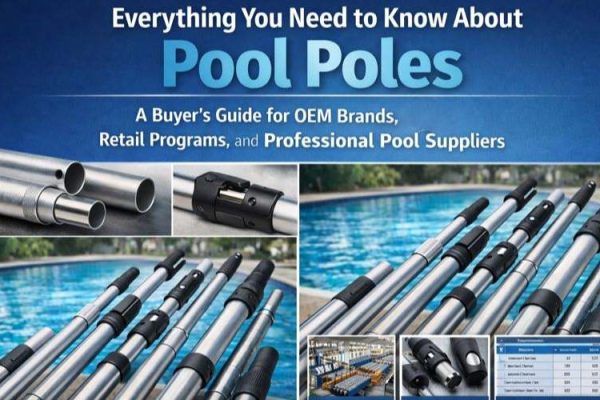

A Buyer’s Guide for OEM Brands, Retail Programs, and Professional Pool Suppliers

Pool poles may look simple, but for buyers, they are a high-impact product. A small change in material, wall thickness, or locking design can affect user feedback, return rates, and long-term brand reputation.

This guide breaks down pool poles from a procurement and OEM perspective, with clear specs, tables, and real-world buying tips you can use immediately.

What a Pool Pole Really Is (From a Buyer’s Perspective)

A pool pole is not just an aluminum tube. It is a system made of several components that must work together consistently at scale.

Key elements buyers evaluate:

- Aluminum tube: defines strength, weight, and cost

- Locking mechanism: determines usability and complaint rate

- Grip/handle: affects comfort and perceived quality

- Tool interface: must fit standard pool attachments

In retail programs, pool poles are often returned not because they break, but because they feel loose, slip under load, or don’t extend smoothly. These issues usually trace back to spec decisions made early in sourcing.

The 5 Core Specifications That Drive Cost and Performance

1. Length Range (Collapsed vs. Extended)

Length is the first spec buyers choose because it defines usage and SKU strategy.

- 4–12 ft: spas, small pools, compact packaging

- 8–16 ft: mainstream residential pools, best-selling retail size

- 12–24 ft: large pools and professional maintenance

Longer reach increases leverage stress, which means diameter and wall thickness must increase to maintain stiffness.

2. Tube Diameter (OD)

Outer diameter affects both rigidity and user feel.

- Smaller OD: lighter, lower cost, more flex

- Larger OD: stiffer, more durable, higher material cost

3. Wall Thickness

Wall thickness is one of the fastest ways to change performance.

- Thinner walls reduce cost and weight

- Thicker walls improve dent resistance and reduce wobble

4. Number of Sections

More sections allow compact packaging but increase joint complexity.

- Fewer sections: stronger feel, longer cartons

- More sections: smaller cartons, higher joint tolerance requirements

5. Locking Mechanism

Lock design often has more impact on complaints than alloy choice.

- External cam locks

- Internal cam locks

- Button or snap locks

- Dual-lock designs

Locking Mechanisms Explained (and How They Fail)

External Cam Lock

- Easy to operate with wet hands

- Visible wear over time

- Can slip if cam material or tolerances are inconsistent

Internal Cam Lock

- Cleaner appearance

- Better protection from dirt

- Harder to service if internal parts wear

Button / Snap Lock

- Simple structure

- Limited load resistance

- Best for short poles only

What Buyers Should Test

- Repeated extend/retract cycles

- Holding force under load

- Operation with wet or sandy hands

Material Choices in the Market

Most pool poles sold globally fall into three material categories:

- Aluminum: best balance of cost, weight, and durability

- Fiberglass: non-conductive, heavier, mid-range pricing

- Carbon fiber: lightweight, premium pricing, niche demand

For OEM and retail programs, aluminum dominates due to consistent extrusion quality and scalable production.

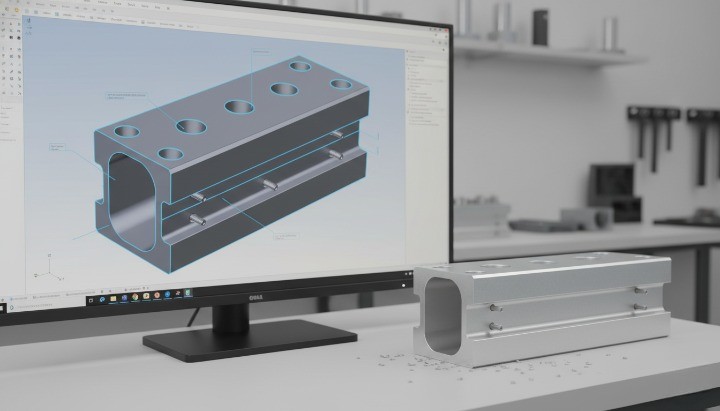

Aluminum Alloy Selection for Pool Poles

Common alloys used in pool pole production include 6061, 6063, 6005, and 6065.

Practical buying guidance:

- Retail private label programs prioritize surface consistency and dent resistance

- Professional service poles prioritize stiffness and load stability

- Anodizing appearance varies by alloy and extrusion control

A stable alloy choice combined with controlled extrusion tolerances reduces batch-to-batch variation—critical for large retail orders.

Specification Tables Buyers Actually Use

Table 1: Length Range vs. Recommended Use

| Length Range | Typical Use Case | Channel |

|---|---|---|

| 4–12 ft | Spas, small pools | Retail / Online |

| 8–16 ft | Residential pools | Retail hero SKU |

| 12–24 ft | Large pools | Commercial / Pro |

Table 2: Spec → Outcome

| Spec Change | Result |

|---|---|

| Larger diameter | Higher stiffness, higher weight |

| Thicker wall | Better dent resistance, higher cost |

| More sections | Compact packaging, higher joint risk |

Table 3: Lock Type Comparison

| Lock Type | Ease of Use | Holding Strength | Serviceability |

|---|---|---|---|

| External cam | High | Medium–High | Easy |

| Internal cam | Medium | High | Medium |

| Button lock | High | Low | Easy |

OEM & Private Label Buyer Checklist

Before issuing an RFQ, define:

- Length range and number of sections

- Tube diameter and wall thickness

- Lock type and materials

- Surface finish (anodized color tolerance)

- Grip design and tool interface

For retail programs:

- Color box vs. master carton packaging

- Barcode placement and labeling

- Drop-test requirements

Clear upfront definitions reduce sampling cycles and prevent costly rework.

Quality Control: What Should Be Inspected

Key inspection points:

- Alloy verification and hardness testing

- Wall thickness and straightness

- Lock function and extension smoothness

- Surface finish and cosmetic consistency

- Final assembly and carton drop testing

A simple pre-production → pilot → mass production inspection flow significantly lowers first-order risk.

Lead Time, MOQ, and First-Order Risk Control

Typical considerations:

- MOQ depends on size range, tooling, and finish

- Custom locks or grips increase lead time

- Carton length directly affects freight cost and container loading

Risk reduction tips:

- Start with one or two core sizes (often 8–16 ft)

- Lock key components early

- Request pre-shipment inspection reports

Why Buyers Choose Xingyong as Their Pool Pole Manufacturer

Xingyong has been manufacturing aluminum products since 2002, supporting OEM brands and retail programs worldwide.

What buyers value:

- 14 aluminum extrusion lines covering multiple tonnage ranges

- Monthly capacity of 3,000 tons for a stable supply

- In-house anodizing, CNC machining, and assembly

- Full inspection capability from alloy analysis to final product checks

- Experience with private label, OEM, and mass-retail requirements

If you are scaling a pool pole program, consistency matters as much as price.

Buyer FAQ

What is the most common retail pool pole size?

8–16 ft remains the most widely used size for residential pools.

Which lock type has fewer complaints?

Well-designed cam locks with controlled tolerances perform best over time.

Is anodized aluminum better than powder coating?

Anodizing offers better scratch resistance and long-term appearance for pool environments.

What should a pre-shipment QC report include?

Dimensional checks, lock function results, surface inspection, and packaging verification.

Ready to Source Pool Poles with Confidence?

Whether you are launching a private label line or optimizing an existing SKU range, clear specifications and reliable manufacturing make the difference.

Request a sample, download the technical spec sheet, or contact our export team to discuss your pool pole program.