Standard Aluminum Extrusion Profiles Manufacturer in China

Xingyong is your trusted Standard Aluminum Extrusion partner in China. We combine over 20 years of experience with advanced technology to supply high-quality profiles to global brands, retailers, and industrial clients.

High-grade raw ingots guarantee stable chemical composition for structural durability.

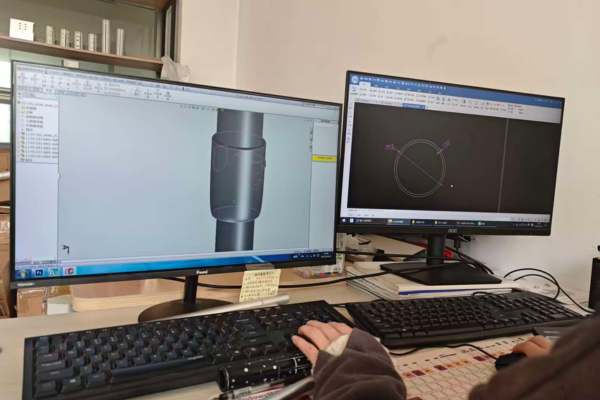

Complete custom manufacturing from extrusion to precision CNC machining.

- ISO certified quality control for reliable standard aluminum shapes.

What is Standard Aluminum Extrusion

Standard Aluminum Extrusion refers to ready-made metal shapes used for building and manufacturing. These profiles—such as angles, channels, tubes, and beams—are pre-designed, which means you do not need to pay for new molds. Made from strong aluminum alloys like 6061 or 6063, they are lightweight, rust-resistant, and easy to cut or drill. You will see them everywhere, from machine frames to window tracks. They are the best choice when you need a quick, affordable, and reliable structural solution for your project.

| Attribute | Specification Details |

|---|---|

| Product Name | Standard Aluminum Extrusion Profiles |

| Alloy Grade | 6000 Series (6061, 6063, 6005) |

| Temper | T3, T4, T5, T6, T8 |

| Available Shapes | Angle (L), Channel (U), T-Bar, I-Beam, Flat Bar, Round Tube, Square/Rectangular Tube, Z/F/H/Y/G Sections |

| Surface Finish | Mill Finish, Anodized (Clear, Black, Bronze, Gold), Sandblasting, Powder Coating, Electrophoresis, Wood Grain |

| Standard Length | 3m – 6m (Custom cutting available upon request) |

| Wall Thickness | 0.8mm to 5.0mm (Depending on profile size) |

| Deep Processing | Precision Cutting, Drilling, Punching, Milling, CNC Machining, Bending, Deburring |

| Certifications | ISO 9001:2015, ISO 14001:2015, IATF 16949:2016, SGS |

| Application | Industrial Framing, Automation lines, Construction, Architectural Trim, Transport Systems, Furniture |

Xingyong Standard Aluminum Extrusion Profile Types

Looking for a reliable source for your inventory? We offer a comprehensive range of Standard Aluminum Extrusion shapes designed to meet diverse industrial and commercial requirements. Whether you are a wholesaler stocking up for construction projects or an manufacturer needing precise components, our profiles deliver consistent quality and dimensional accuracy.

Shapes Of Standard Aluminum Extrusion

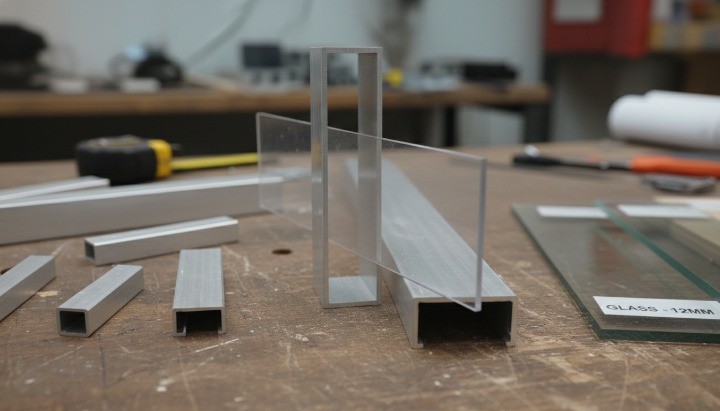

Extruded Aluminum Channel (U Shape)

Specialty Section Profiles Of Standard Aluminum Extrusion

aluminum h profile

aluminum z profile

y section aluminium extrusion

Simple Profiles Of Standard Aluminum Extrusion

rectangular aluminum tubing

Oval Aluminum Extrusion

Aluminum Flat Bar

Why Choose Xingyong Standard Aluminum Extrusion

At Xingyong, we deliver premium Standard Aluminum Extrusion with smooth finishes and high durability. Partner with a manufacturer that supports your supply chain with stable quality and on-time delivery.

Superior Raw Materials For Standard Aluminum Extrusion

Our Standard Aluminum Extrusion starts with top-grade 6061 and 6063 alloys. We strictly control chemical composition to ensure superior corrosion resistance and consistent strength for every profile.

Uses pure 6000 series aluminum alloys.

Materials resist corrosion effectively.

Consistent metal grain structure.

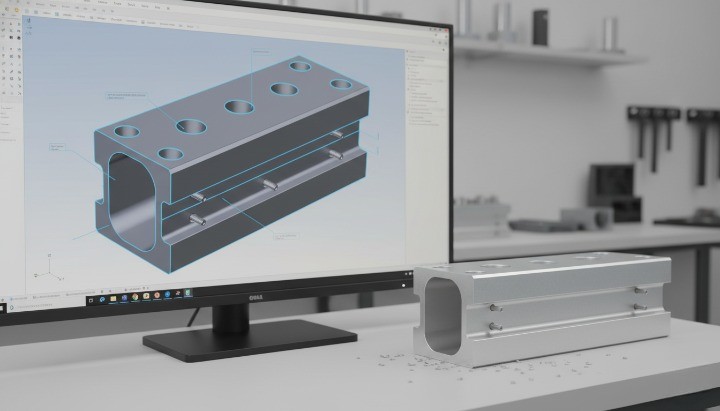

Customization and Deep Processing For Standard Aluminum Extrusion

We deliver ready-to-assemble Standard Aluminum Extrusion components. From precise cutting to complex CNC machining and custom anodizing, our one-stop fabrication service saves you time and handling costs.

In-house CNC, drilling, and punching.

Custom anodizing and sandblasting available.

Manufactured to your exact drawings.

Certified Quality Control For Standard Aluminum Extrusion

Trust our ISO 9001:2015 certified process. We use advanced spectrometers and scanners to verify the hardness and dimensions of every Standard Aluminum Extrusion batch before shipping.

Certified under ISO and IATF standards.

Rigorous testing for hardness and tension.

Full traceability for every batch.

FAQ of Standard Aluminum Extrusion

Do I need to pay for new molds for Standard Aluminum Extrusion shapes?

Generally, no. Since these are Standard Aluminum Extrusion profiles like angles, channels, and tubes, we likely already have the open molds in our library. This saves you the initial tooling cost and speeds up production time compared to custom-designed shapes. If you need a very specific dimension that is slightly different from standard sizes, a small mold fee might apply.

What specific alloys and tempers do you use?

We primarily manufacture Standard Aluminum Extrusion using 6000 series alloys. The most common is 6063 T5, which offers a great balance of strength and surface finish quality, making it perfect for architectural use. For structural applications requiring higher tensile strength, we supply 6061 T6. We can also adjust the temper to meet your specific hardness requirements based on our rigorous ISO testing standards.

What are your standard length and cutting tolerances?

Our standard production length is usually between 3 to 6 meters to fit shipping containers, but we can cut to any specific length you require. For Standard Aluminum Extrusion, we maintain strict dimensional tolerances according to GB high-precision levels or EN 755 standards. Our cutting precision can be controlled within very tight margins using our advanced saw machines, ensuring easy assembly on your end.

How do you control surface defects like die lines or scratches?

We treat surface quality seriously by regularly maintaining our extrusion dies and strictly controlling the extrusion speed to minimize die lines. Our quality team performs visual inspections under professional lighting to ensure every piece of Standard Aluminum Extrusion is free from deep scratches, blisters, or uneven coloring before it is approved for packaging.

Does your Standard Aluminum Extrusion meet strict straightness and twist tolerances?

Yes, we adhere to high-precision standards (such as EN 755 or GB/T 5237) for straightness and twist. Using our automated straightening machines and on-site detection tools, we verify that every length of Standard Aluminum Extrusion remains perfectly straight and free from twisting, ensuring it fits seamlessly into your framing or track systems without issues.

Related Product Of Standard Aluminum Extrusion

Expand your catalog with our finished aluminum solutions. Beyond raw Standard Aluminum Extrusion, we manufacture high-quality Aluminum Telescopic Poles and Pool Cover Reels. Boost your sales with our ready-to-market products. Explore the full range now.

Telescopic Pool Pole

Solar Panel Cleaning Telescoping Pole

Dusting Extension Pole

Tent Poles Aluminum (Telescoping Type)

Technical Support for Standard Aluminum Extrusion

Gain expert insights on Standard Aluminum Extrusion design and alloys. Our technical blog helps you overcome manufacturing challenges and optimize your supply chain with professional advice. Visit our knowledge base today.

Contact Us

Ready to order Standard Aluminum Extrusion? Fill out the form for a competitive factory-direct quote today.

- No. 222, Huaihe East Road, Huaiyin District, Huaian City Jiangsu, China

- info@poolple.com

- (+86)159-9616-7132