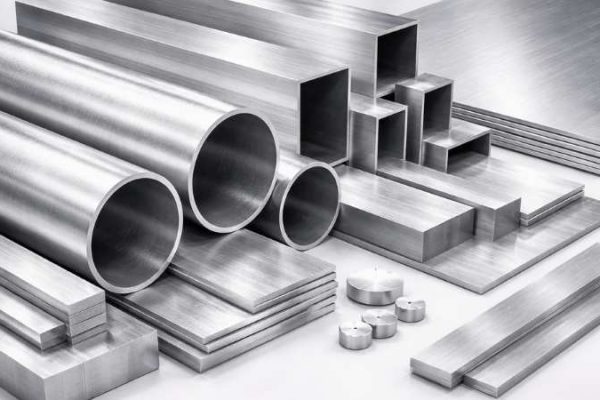

Mill finish aluminum is aluminum in its natural, untreated surface state after extrusion, rolling, or forming.

It comes straight from the mill—no anodizing, no polishing, no coating. What you see is the aluminum exactly as it leaves the production line.

For many OEM buyers and procurement teams, mill finish aluminum is not a shortcut. It’s a starting point.

What Does “Mill Finish” Actually Mean?

In simple terms, mill finish means:

- The aluminum has not received any surface treatment

- No anodizing, powder coating, brushing, or polishing

- The surface reflects the extrusion or rolling process itself

This is the default condition of aluminum profiles, tubes, and sheets once they are produced and cut to length.

What mill finish does not mean:

- ❌ Not polished

- ❌ Not corrosion-protected

- ❌ Not appearance-controlled

Understanding this distinction helps avoid confusion during sourcing and inspection.

What Does Mill Finish Aluminum Look Like?

Mill finish aluminum typically has:

- A natural silver-gray color

- Visible extrusion lines or roller marks

- Slight variations in gloss and texture

These variations are normal. They come from tooling, billet quality, and process conditions—not from defects.

From real production experience:

- Larger extrusion presses (like 1400T–2000T) often produce more stable wall thickness, but surface lines may be more visible

- New dies leave sharper lines; worn dies create softer patterns

- Different billets can create small color shifts between batches

This is why mill-finish aluminum is rarely used for visible consumer-facing parts.

How Mill Finish Aluminum Is Made (Extrusion View)

Most mill finish aluminum used in poles, tubes, and profiles comes from extrusion.

The basic steps are:

- Aluminum billets are heated to around 450–500 °C

- The billet is pushed through a precision die

- The profile is cooled, stretched, and cut

- No surface treatment is applied

At this stage, the aluminum is dimensionally accurate but visually raw.

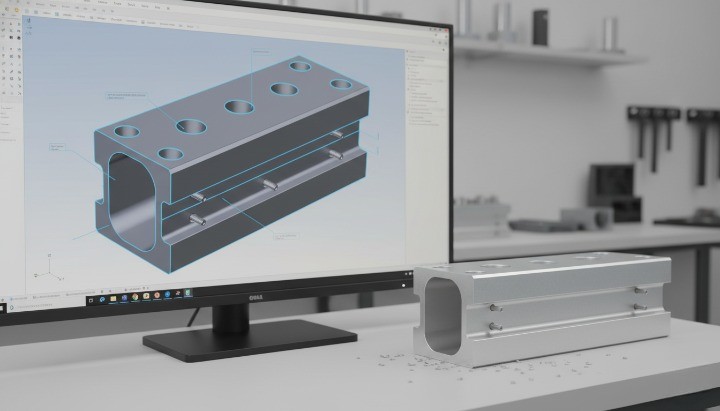

Many OEM buyers choose mill finish because it allows:

- Secondary anodizing or powder coating later

- Cutting, drilling, and CNC machining without damaging a finished surface

- Lower material cost during early-stage production

Pros and Cons of Mill Finish Aluminum

Advantages

- Lowest cost aluminum surface option

- Shortest lead time (no finishing queue)

- Ideal for secondary processing

- Easier to inspect dimensional accuracy

Limitations

- Inconsistent appearance

- Lower corrosion resistance compared to anodized aluminum

- Fingerprints and stains show easily

- Not suitable for exposed outdoor or retail products

For cost-driven or internal components, these trade-offs often make sense.

Mill Finish Aluminum vs Anodized Aluminum

| Aspect | Mill Finish Aluminum | Anodized Aluminum |

|---|---|---|

| Surface | Raw, untreated | Electrochemically protected |

| Appearance | Varies by batch | Uniform and controlled |

| Corrosion resistance | Basic | Strong |

| Cost | Lower | Higher |

| Typical use | Structural, internal | Visible, outdoor |

Procurement reality:

Large retail programs (Walmart, Home Depot, ROSS) almost never accept mill finish for visible parts.

Industrial OEMs often prefer mill finish for inner tubes or hidden components.

Common Applications of Mill Finish Aluminum

Mill finish aluminum is commonly used for:

- Structural frames

- Internal support parts

- Telescopic tube inner sections

- Components to be anodized or coated later

- Industrial fixtures and jigs

In aluminum telescopic poles, mill finish is often used for:

- Inner sliding tubes

- Parts that never face the end user

- Cost-sensitive OEM projects

Is Mill Finish Aluminum Right for Your Project?

Before choosing mill finish aluminum, ask:

- Will the part be visible to the end user?

- Will it be used outdoors or indoors?

- Will you apply anodizing or coating later?

- Is surface consistency critical to your brand?

Mill finish works best when:

- Appearance is not critical

- Cost control matters

- Secondary finishing is planned

Avoid mill finish when:

- The product is consumer-facing

- Color consistency is required

- Long-term outdoor exposure is expected

FAQ: Mill Finish Aluminum

Can mill finish aluminum be anodized later?

Yes. Mill finish is often the preferred starting surface for anodizing.

Does mill finish aluminum rust?

Aluminum does not rust like steel, but untreated surfaces can oxidize and stain over time.

Why does my shipment look different from the sample?

Small differences in billet source, die condition, or production batch can change surface appearance.

How long can mill finish aluminum be stored?

When kept dry and protected, it can be stored for months. Long-term storage requires proper packaging.

Working with a Reliable Aluminum Extrusion Partner

At Xingyong, we’ve produced aluminum extrusions since 2002, with:

- 14 extrusion lines from 350T to 2000T

- Monthly capacity of 3,000 tons

- In-house anodizing, sandblasting, and CNC processing

- Full inspection using spectrometers, hardness testers, and section scanners

For many OEM customers, mill finish aluminum is the first step—not the final product.

We help you decide when it makes sense and when it doesn’t.

Request a sample

Contact our export team