Aluminum ingots are one of the most widely traded industrial metals in the world. For pool-cleaning tool brands, understanding their value is more than a curiosity—it directly impacts the cost, stability, and profitability of your telescopic pole product line.

This guide breaks down real price ranges, market drivers, and what the numbers mean for your purchasing decisions.

What Exactly Is an Aluminum Ingot?

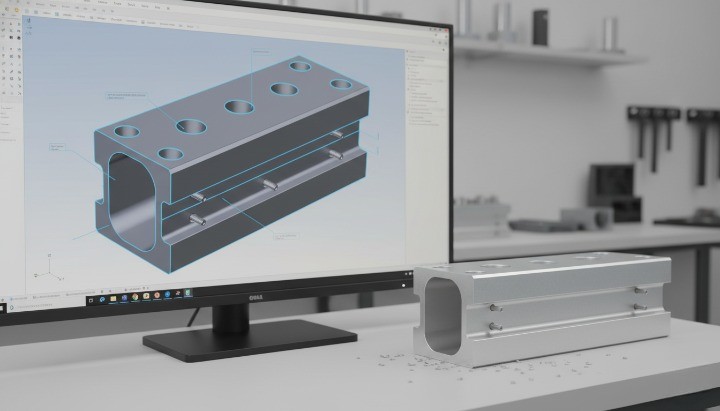

Aluminum ingots are solid blocks of refined aluminum that serve as the base material for extrusion billets, tubes, and ultimately the telescopic poles used in pool-cleaning tools. They’re produced after smelting bauxite into alumina and refining it into primary aluminum.

- Primary aluminum ingot comes directly from smelters and is the preferred material for extrusion-grade 6063/6061 tubes.

- Secondary (recycled) ingot is cheaper but not suitable for high-quality telescopic poles due to unstable chemical composition.

- For OEM buyers, knowing your supplier’s billet source protects you from unexpected strength, hardness, or anodizing issues.

How Valuable Are Aluminum Ingots Today? (2025 Market Overview)

Aluminum is a globally traded commodity, mainly priced through the London Metal Exchange (LME).

As of early 2025:

- Primary aluminum ingot: USD $2,150 – $2,350 per metric ton

- Extrusion billet (6063/6061): USD $2,300 – $2,550 per ton

- Scrap aluminum: USD $0.60 – $1.10 per lb (not used for quality telescopic poles)

Price differences occur due to alloy purity, smelting cost, and market demand.

For OEM buyers, the key number to track is the extrusion billet price, because this is what becomes your aluminum pole tubing.

At a glance:

- Ingot = base metal

- Billet = extrudable form (your real cost)

- Pole = billet + extrusion + finishing + labor + packaging

Aluminum Ingot Price Breakdown — What Are You Really Paying For?

When you buy finished aluminum telescopic poles, 60–75% of the cost usually comes from the material itself.

Typical cost structure for a 3–4 section aluminum pole:

| Cost Component | Percentage | Notes |

|---|---|---|

| Raw aluminum (billet) | 60–75% | Depends on wall thickness and weight |

| Extrusion (pressing) | 10–15% | Requires 350–2000 ton extrusion machines |

| Surface finishing | 8–12% | Anodizing or powder coating |

| Labor & overhead | 5–10% | Depends on desi |