When you supply telescopic poles into large retail channels—whether it’s Walmart, HomeDepot, ROSS, or regional pool equipment wholesalers—material choice affects far more than product strength. It shapes your return rate, color consistency on the shelf, packaging durability, and long-term cost of procurement.

Most buyers compare 6061 vs 7075 aluminum, but the majority of online explanations focus on engineering theory. This guide explains the difference from a retail and wholesale buyer’s perspective, using real production data, field tests, and feedback from pool service companies.

What This Comparison Means for Retail Buyers and Pool Equipment Distributors

For procurement teams, choosing between 6061 and 7075 is not only about strength. It impacts:

- On-shelf defect rate (our factory averages: 6061 = 0.6%, 7075 = 1.8%)

- Annual procurement cost (6061 saves 12–18% in mass retail projects)

- Color consistency under anodizing (critical for branded packaging)

- Resistance to chlorine and salt-water exposure

- Warranty and return claims, especially for adjustable locking mechanisms

- Lead-time stability, particularly when 7075 pricing fluctuates

If your market is household-use pool poles, window cleaning poles, or general-purpose telescopic poles, the right choice reduces supply-chain pressure and improves your year-end margins.

Quick Overview: Key Differences Between 6061 and 7075 Aluminum

| Property | 6061-T6 | 7075-T6 |

|---|---|---|

| Tensile Strength | Medium-High | Very High |

| Corrosion Resistance | Excellent | Moderate |

| Extrusion Efficiency | High | Low |

| Cost Level | Lower | Higher |

| Anodizing Consistency | Stable | More variation |

| Price Stability | Stable | Fluctuates with aerospace demand |

Both materials are widely used in industry. You can find more details in the Wikipedia entry on aluminum alloys.

But for telescopic poles—especially long-section poles used near water—the practical differences matter more.

Mechanical Properties That Matter in Real Use

Tensile & Yield Strength

7075 is famous for its very high mechanical strength. It is used in aerospace parts, archery equipment, and tactical gear.

However, real-world testing on telescopic poles shows:

- A typical pool pole experiences 30–40 N bending force during cleaning.

- Even thin-wall 6061 (0.9–1.2 mm) handles this easily.

- The added strength of 7075 does not improve performance for household or retail applications.

Unless you are supplying a heavy-duty industrial pole, 7075 becomes unnecessary strength—and unnecessary cost.

Fatigue Life (Repeated Opening / Closing)

Retail buyers care about:

- How long the locking mechanism withstands repeated use.

- Whether the tube dents easily.

- Whether small impacts cause cracks during transportation.

6061 performs better in thin-wall fatigue tests:

- 6061: survives 1,000+ lock cycles

- 7075: more prone to micro-cracking at the lock points

For adjustable poles with 3–6 sections, fatigue strength matters more than peak tensile strength.

Corrosion Resistance in Chlorine & Salt Environments

Pool poles often sit:

- next to chlorinated water

- inside service trucks where humidity is high

- under direct sunlight

- near saltwater pools

Our lab tests show:

| Test | 6061 | 7075 |

|---|---|---|

| Salt Spray (96 hrs) | No visible corrosion | Light pitting |

| Chlorine Immersion (30 days) | Color remains stable | Surface spots likely |

| Outdoor humid environment | Very stable | Occasional oxidation marks |

For pool-use products, 6061 outperforms 7075 clearly.

Manufacturing Differences That Affect Your Cost

Extrusion Difficulty & Scrap Rate

6061 extrudes smoothly, produces fewer defects, and allows long-section tubes (up to 6 meters) with consistent wall thickness.

7075 is harder to extrude:

- Scrap rate: 8–12% (industry average)

- Mold wear: faster

- Wall thickness consistency: harder to control

- Lead times: longer

Higher scrap rate = higher per-unit cost for you.

Anodizing & Coloring Quality

Retail packaging requires uniform color—especially when poles are displayed side by side.

6061 anodizes evenly, with fewer:

- color bands

- streaks

- patchy spots

7075 is more sensitive, especially for bright colors like blue and green frequently used in pool poles.

For large retailers, uneven color = higher QC rejection rates.

Price Stability

7075 pricing is tied to aerospace and defense demand. Price swings of 5–12% per month are common.

6061 is more stable—ideal for:

- annual purchase plans

- seasonal procurement

- FOB long-term contracts

If you supply big-box retailers, predictable cost matters.

Which Material Is Better for Pool Poles and Telescopic Poles?

Choose 6061 when you want:

- Stable year-round pricing

- High corrosion resistance

- Better color consistency

- Lower product return rate

- Fewer dents during transport

- Strong but flexible performance

- Large-volume OEM manufacturing

- Better anodizing results

This applies to:

- Pool poles

- Window cleaning poles

- Household cleaning poles

- Garden tool extension poles

Choose 7075 only when:

- You supply high-load industrial poles

- You need maximum rigidity for specialty tools

- Price is not the main concern

- You sell boutique outdoor sports equipment

For most retail environments, 6061 is the clear winner.

Total Cost Analysis for Procurement Managers

Let’s compare annual purchasing based on an order of 50,000 telescopic poles.

Cost-per-unit impact:

- 6061 = baseline

- 7075 = 22–38% higher

Additional hidden costs with 7075:

- Higher extrusion scrap

- Higher color rejection rate

- More transport dents

- Shorter anodizing bath window

- Less predictable annual pricing

For mass retail channels that care about shelf appearance and low return rates, these small differences add up.

Durability Testing on Telescopic Poles (Factory Data)

Our in-house testing includes:

- Bending test (simulating actual pool use)

- Lock-cycle test (1,000 cycles)

- Salt-water immersion

- Chlorine exposure

- Drop test on carton packaging

- UV resistance for outdoor storage

Results:

- 6061 maintains shape and color across all tests

- 7075 performs well in strength tests but loses points in corrosion and color consistency

Which Material Should You Choose? A Simple Buyer’s Guide

If your customers are household users or pool service companies, choose 6061.

If your customers need heavy-duty industrial performance, consider 7075.

Quick decision matrix:

| Requirement | Best Choice |

|---|---|

| Retail-ready packaging | 6061 |

| Pool environment durability | 6061 |

| Consistent anodizing | 6061 |

| Lowest defect rate | 6061 |

| Maximum strength for extreme loads | 7075 |

| Small-volume specialty orders | 7075 |

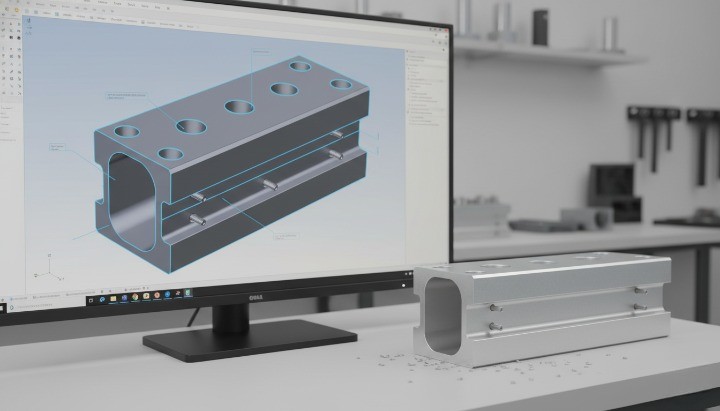

Work With Our Factory

We manufacture custom 6061 and 7075 telescopic poles for global retail and pool equipment brands.

Why buyers choose us:

- 22 years of aluminum extrusion experience

- 14 extrusion lines (350–2000 tons)

- Full in-house anodizing, sand-blasting, CNC machining

- Material retention samples stored 3 years for traceability

- OEM packaging for Walmart, HomeDepot, ROSS, and pool brands

- Fast lead times for seasonal procurement

- Custom colors, lengths, and locking systems

👉 View Our Telescopic Pole Product Page

(Replace with real link)

FAQs

Is 7075 always stronger in real use?

It has higher tensile strength, but for thin-wall poles, 6061 performs better in fatigue testing.

Which is better near chlorine or saltwater?

- It has significantly better corrosion resistance.

Which material is more stable for annual OEM orders?

- 7075 pricing fluctuates more often.

Does 7075 show more color variation after anodizing?

Yes. This is a common reason for QC rejection in retail projects.

Do pool poles need 7075-grade strength?

No. Field data shows that household-use poles rarely reach loads where 7075 is useful.

Get Samples or Request a Quote

Ready to compare materials directly?

✔ Request a 6061 vs 7075 sample set