Premier 6063 Aluminum Tube Manufacturer in China

Since 2002, Xingyong has provided high-quality custom 6063 aluminum tubing to global buyers.

What is 6063 Aluminum Tube?

6063 aluminum tube is often called the “architectural alloy” because it has a very smooth surface. It is perfect for parts that need to look good, like furniture, rails, and window frames. This metal resists rust and is easy to shape, bend, or anodize with color. While it is not as strong as 6061, our 6063 aluminum tubing offers better corrosion resistance and a finer finish. Whether you need round or square shapes, this material works great for both outdoor and indoor projects.

| Parameter | Details |

|---|---|

| Product Name | 6063 Aluminum Tube / Pipe |

| Alloy Grade | AA 6063 (Al-Mg-Si Alloy) |

| Temper / Hardness | T5 (Architectural), T6 (Structural), T4, T52 (Bending capable) |

| Available Shapes | Round, Square, Rectangular, Oval, Custom Extruded Profiles |

| Outer Diameter (OD) | 6mm – 220mm (Customizable via 2000T Press) |

| Wall Thickness | 0.5mm – 20mm (Uniform thickness control) |

| Standard Length | 3m – 6m, or precision cut to size (e.g., telescopic pole lengths) |

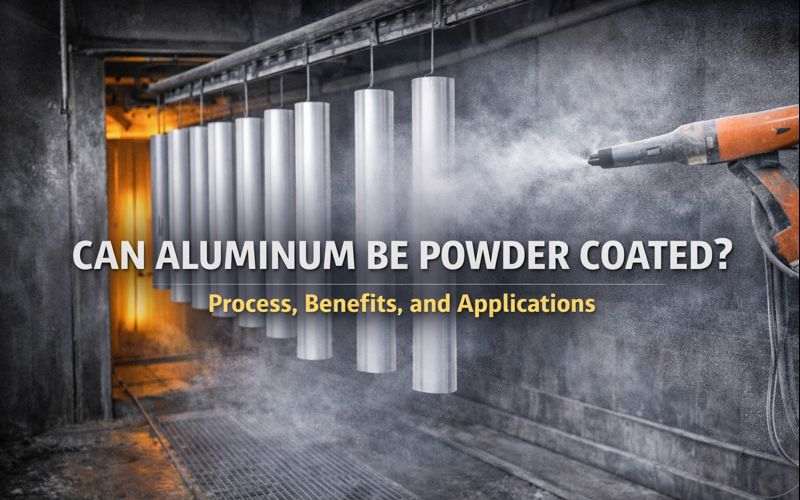

| Surface Finish | Anodized (Silver, Black, Bronze, Gold), Powder Coated, Polished, Sandblasted, Mill Finish |

| Anodizing Film | 8 – 25 microns (µm) based on requirement |

| Manufacturing Standards | ASTM B221, EN 755, GB/T 5237 |

| Deep Processing | CNC Machining, Bending, Drilling, Punching, Expanding, Laser Marking |

| Certifications | ISO 9001:2015, IATF 16949, ISO 14001, BSCI, CE |

Xingyong 6063 Aluminum Tube Series

At Xingyong, we offer a diverse selection of 6063 aluminum tube specifications to match your inventory needs. Whether you are sourcing materials for lightweight frames or heavy-load structures, our 6063 aluminum tubing delivers the right balance of strength and aesthetics. Browse our classification below to find the exact shape and temper for your business.

6063 Aluminum Tube By Shape & Profile

6063 Aluminum Round Tube

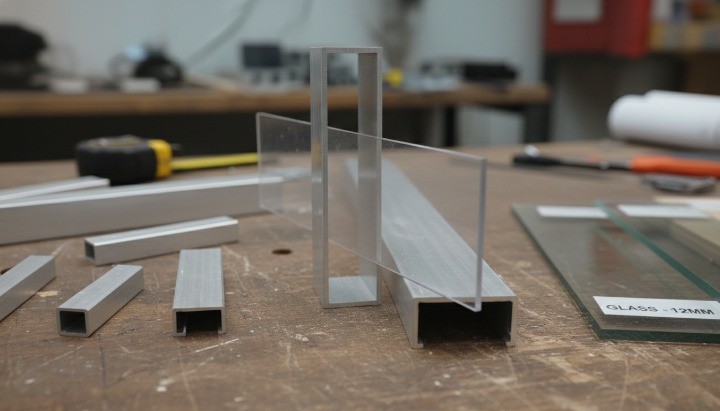

6063 Aluminum Square Tube

6063 Aluminum Rectangular Tube

Extruded 6063 Aluminum Profiles

Hollow Aluminum Section 6063

6063 Aluminum Profiles By Temper & Hardness

6063 T4 Aluminum Tube

6063 T5 Aluminum Tube

6063 T6 Aluminum Tube

6063 T52 Aluminum Tube

6063 Aluminum Tube By Surface Finish & Process

Anodized 6063 Aluminum Tube

Powder Coated 6063 Aluminum Tubing

Polished 6063 Aluminum Pipe

Seamless 6063 Aluminum Tube

6063 Aluminum Tube By Application & Industry

Telescopic 6063 Aluminum Pole

Architectural Aluminum Tubing 6063

Marine Grade 6063 Aluminum Tube

6063 Aluminum Tube By Dimensions & Standards

ASTM B221 6063 Aluminum Tube

Thin Wall 6063 Aluminum Tubing

Large Diameter 6063 Aluminum Pipe

Why Choose Xingyong 6063 Aluminum Tube

At Xingyong, we combine decades of expertise with advanced technology to deliver 6063 aluminum pipe that meets global standards. Whether you need durable poles or precision profiles, our 6063 aluminum tube ensures value and quality. Partner with us for a seamless manufacturing experience.

Premium Raw Materials for Superior Alloy Performance

Pure Composition: Verified purity prevents surface defects.

Better Formability: Ideal for smooth bending without cracking.

Consistent Strength: Meets T5 or T6 hardness standards reliably.

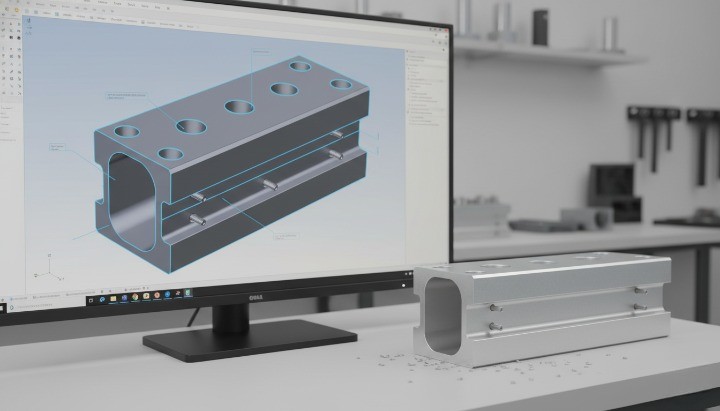

One-Stop Custom 6063 Aluminum Tubing Solutions

Full Fabrication: In-house CNC, bending, and punching.

Brand Customization: Laser marking and custom retail packaging available.

Design Support: We create unique molds from your drawings.

Rigorous Testing for Certified 6063 Aluminum Pipe

Global Standards: ISO 9001, ISO 14001, and IATF 16949 certified.

Precise Inspection: Testing for strength and color consistency.

Traceability: Full documentation for total quality accountability.

FAQ of Aluminum Railing

What is the difference between 6061 and 6063 aluminum tube?

The main difference is their surface finish and strength. 6061 vs 6063 aluminum tube comparisons show that 6061 is stronger and used for structural heavy loads, while 6063 is known as the “architectural alloy.” 6063 has a much smoother surface, making it the best choice for anodizing, visible architectural trim, and furniture where aesthetics matter more than raw tensile strength.

Can 6063 aluminum tube be bent without cracking?

Yes, but the temper matters. A standard 6063 T6 aluminum tube is very hard and may crack if bent sharply. For bending 6063 aluminum tube projects, we recommend ordering T4 or T52 tempers, which are softer and highly formable. After bending, we can heat treat the finished part to T6 to restore its strength.

What is the difference between T5 and T6 tempers?

The difference lies in how they are cooled. 6063 T5 aluminum tube is air-cooled at the press and artificially aged, offering medium strength and a great finish for general use. 6063 T6 aluminum tube is water-cooled (quenched) for maximum hardness and strength. T6 is preferred for load-bearing parts, while T5 is standard for windows and trim.

Is 6063 aluminum tubing suitable for anodizing?

Absolutely. In fact, 6063 aluminum tubing is the best alloy for anodizing. Its high purity allows it to take color consistently and form a uniform, protective oxide layer. At Xingyong, our automatic anodizing lines can produce silver, black, bronze, or custom colors that resist fading and scratching better than other alloys.

Does 6063 aluminum pipe rust in outdoor or marine use?

No, it is highly resistant to corrosion. 6063 aluminum pipe is often called “marine grade” for architectural use because it lacks copper, which causes corrosion in other alloys. This makes it perfect for swimming pool poles, irrigation systems, and boat railings exposed to water and humidity.

Related Product Of 6063 Aluminum Tube

Expand your inventory with our finished telescopic aluminum poles and pool cover reels. Crafted from high-quality anodized 6063 aluminum tubing, these durable, rust-proof solutions are fully customizable for your brand. Click to explore our ready-to-ship finished product lines.

Dusting Extension Pole

Brush Extension Pole

Squeegee Extension Pole

Telescoping Pole Saw

Technical Support for 6063 Aluminum Tube

Need engineering advice? Visit our blog for expert guides on 6063 aluminum tube tempers and fabrication. Learn best practices for bending 6063 aluminum tube and anodizing to optimize your project design.

Contact Us

Get factory-direct pricing on premium 6063 aluminum tube. Fill out the form to receive a fast, competitive quote for your custom project today.

- No. 222, Huaihe East Road, Huaiyin District, Huaian City Jiangsu, China

- info@poolple.com

- (+86)159-9616-7132