6005 Aluminum Tube Manufacturer in China

Sourcing high-strength tubing is easy with Xingyong. We combine over 20 years of extrusion experience with advanced anodizing to deliver custom 6005 and 6005A pipes directly from our factory to your warehouse.

High-grade raw ingots guarantee stable chemical composition for structural durability.

One-stop customized solution with CNC machining, cutting, and packaging services.

- In-house anodizing ensures corrosion resistance for marine and outdoor use.

ISO 9001 and IATF 16949 certified factory guarantees global quality standards.

What is 6005 Aluminum Tube

Xingyong 6005 aluminum tube is a strong metal alloy made with silicon and magnesium. It offers the perfect balance, fitting right between 6061 and 6063 types. This means it is tougher than standard pipes but still keeps a smooth, clean surface. It fights off rust effectively, making it great for outdoor tools, ladders, and marine parts. Our structural aluminum tubing is easy to weld and bend. It gives you reliable strength for your projects without being too heavy or rough.

| Property | Specification Details |

|---|---|

| Material Grade | 6005 / 6005A Aluminum Alloy |

| Temper | T5, T6 |

| Outer Diameter (OD) | 10mm – 300mm (Customizable) |

| Wall Thickness | 0.8mm – 20mm |

| Length | 1m – 6m (Cut-to-length service available) |

| Shape | Round, Square, Rectangular, Oval, Telescopic, Custom Profile |

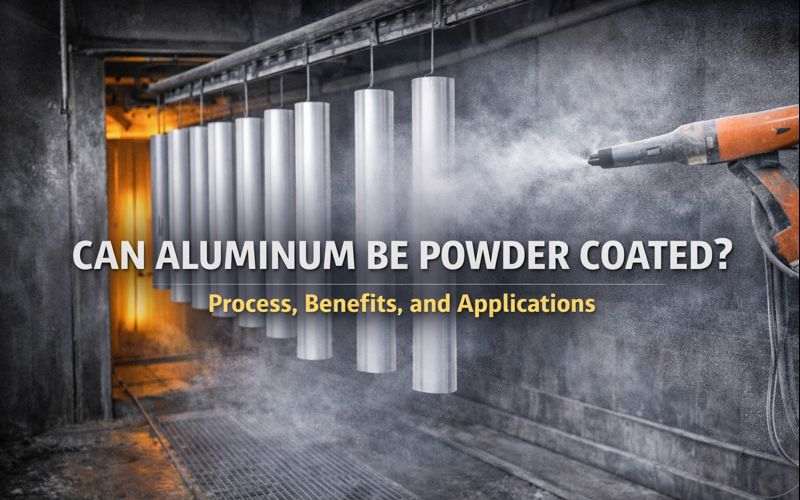

| Surface Treatment | Anodized (Clear, Black, Gold, Custom), Powder Coated, Mill Finish, Sandblasted, Polished |

| Anodizing Thickness | 10µm – 25µm (Marine Grade Available) |

| Deep Processing | CNC Machining, Drilling, Punching, Bending, Laser Marking |

| Tensile Strength | ≥ 260 MPa (T5) |

| Yield Strength | ≥ 215 MPa (T5) |

| Elongation | ≥ 8% |

| Certifications | ISO 9001:2015, IATF 16949:2016, ISO 14001:2015 |

| Standard | ASTM B221, EN 755, GB/T 6892 |

| Typical Applications | Telescopic poles, marine structures, ladders, furniture frames, automotive parts |

Xingyong 6005 Aluminum Tube Product Categories

Finding the exact metal profile for your project is simple with Xingyong. We organize our 6005 aluminum tube products by process, shape, and application to help you navigate quickly and easily. From raw materials to finished telescopic aluminum tubing, our factory delivers quality solutions. Browse the categories below to choose the right fit for your business.

6005 Aluminum Tube By Temper

6005-T5 Aluminum Tube

6005-T6 Aluminum Pipe

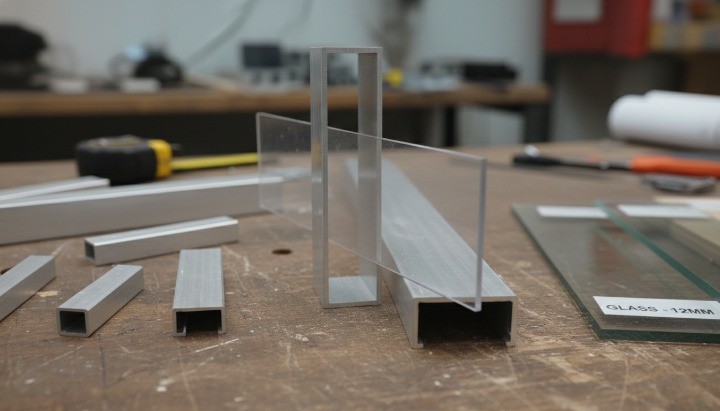

6005 Aluminum Tube By Shape

Round Aluminum Tube

Square Aluminum Tubing

Rectangular Aluminum Box Section

6005 Aluminum Tube By Dimensions

Thin Wall 6005 Aluminum Pipe

Heavy Wall Aluminum Tubing

Large Diameter Aluminum Tube

6005 Aluminum Tube By Industry Applications

Telescopic Aluminum Tubing

Pool Pole Aluminum Tubing

Extension Handle Tubing

Corrosion-Resistant Aluminum Tube for Marine

Boat Railing Aluminum Pipe

Tent Pole Aluminum Tubing

Structural Aluminum Tubing

Aluminum Scaffolding Tube

Aluminum Ladder Profiles

Handrail Aluminum Tubing

Automotive Chassis Profiles

Furniture Aluminum Tubing

6005 Aluminum Tube by Process & Finish

6005A Aluminum Pipe

Extruded Aluminum Tube

Seamless Aluminum Tube

Precision Extruded Aluminum Tubing

Aluminum Hollow Bar

Anodized Aluminum Tube

Sandblasted Aluminum Pipe

Polished Aluminum Tubing

Powder Coated Aluminum Tube

Why Choose Xingyong 6005 Aluminum Tube

When you partner with Xingyong, you gain a stable supply chain backed by decades of manufacturing expertise. We produce high-quality 6005 aluminum tube that meets your strict standards for strength and finish. From controlling the raw alloy mixture to delivering the final packaged product, our factory manages every step under one roof. We help brand manufacturers and global distributors reduce costs and speed up time-to-market. Trust us to deliver consistent 6005A aluminum pipe solutions that keep your business moving forward.

Premium Raw Material Control For 6005 aluminum Tube

Purity: We use high-grade aluminum ingots to prevent structural defects.

Traceability: Every batch is tracked from the melting furnace to the finished tube.

Compliance: Materials meet international alloy standards for global export.

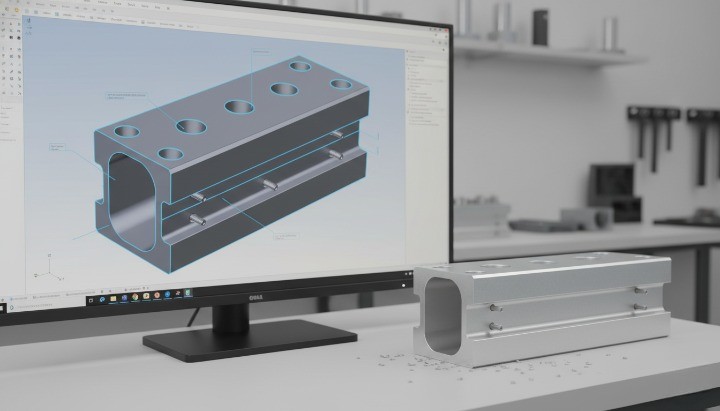

One-Stop Customization Services For 6005 Aluminum Tube

Fabrication: CNC machining, drilling, punching, and bending on-site.

Branding: Laser marking services to put your logo directly on the product.

Packaging: Custom cartoning and labeling for direct-to-shelf delivery.

Certified Quality Assurance in Every 6005 Aluminum Tube

Standards: Fully certified to ISO 9001:2015, ISO 14001:2015, and IATF 16949:2016.

Testing: In-house checks for hardness, film thickness, and tensile strength.

Consistency: Automated monitoring ensures color consistency across anodized batches.

FAQ of 6005 Aluminum Tube

What is the difference between 6005 and 6061 aluminum tube?

6005 aluminum tube sits between 6063 and 6061 in terms of characteristics. It contains higher silicon levels than 6061, which improves its extrudability for complex shapes. While 6061 is slightly stronger, 6005 offers a much smoother surface finish after anodizing and has better corrosion resistance, making it superior for visible architectural and marine parts.

Is 6005A aluminum pipe suitable for welding?

Yes, 6005A aluminum pipe is excellent for welding. Unlike some other 6000-series alloys, 6005A is chemically designed to retain its strength in the heat-affected zone (HAZ) near the weld. This makes it a preferred choice for manufacturing structural frames, ladders, and transport platforms that require secure welded joints.

Can I use your 6005 structural aluminum tubing for marine applications?

Absolutely. This alloy is highly resistant to general atmospheric corrosion and salt water. We frequently supply corrosion-resistant aluminum tube for marine projects, such as boat handrails and dock components. For maximum protection in harsh sea environments, we recommend adding our clear or colored anodized finish to seal the surface.

Do you offer custom shapes for telescopic pole systems?

Yes, this is one of our specialties. We can manufacture telescopic aluminum tubing with specific internal ribs, flutes, or external grooves. Our engineering team ensures strict control over the inner and outer diameters so that the tubes slide smoothly and lock securely, which is critical for pool cleaning poles and extension handles.

What is the typical lead time for a custom extruded aluminum tube order?

For new custom dies, it typically takes 7 to 10 days to create the mold and send you a sample for approval. Once the sample is confirmed, bulk production of your extruded aluminum tube generally takes 15 to 20 days, depending on the order volume and the type of surface treatment required.

Related Product Of 6005 Aluminum Tube

Beyond 6005 aluminum tube, we supply finished aluminum telescopic poles and versatile 6063 aluminum profiles, and swimming pole maintenance. Consolidate your order with Xingyong to save on shipping and simplify sourcing. Explore our related categories to complete your inventory today.

Dusting Extension Pole

Brush Extension Pole

Squeegee Extension Pole

Telescoping Pole Saw

Technical Support for 6005 Aluminum Tube

Maximize project success with our technical resources. Access expert data on 6005 aluminum tube properties, temper selection, and extrusion design tips. We help you optimize performance and reduce costs. Click to explore our engineering guides today.

Contact Us

Need high-quality 6005 aluminum tube? Get factory-direct pricing for custom extrusion or bulk orders. Fill out the form on the right for a fast, free quote today!

- No. 222, Huaihe East Road, Huaiyin District, Huaian City Jiangsu, China

- info@poolple.com

- (+86)159-9616-7132