Aluminum extrusions look simple on paper. In reality, many OEM projects fail during CNC machining—not because of the machine, but because of early design and process decisions. Buyers often assume CNC will “fix everything” after extrusion. That assumption leads to unstable tolerances, rework, and delayed shipments. This guide explains how aluminum extrusions are CNC machined in real factories, what you should plan before sending drawings, and how to control cost, lead time, and quality in OEM production.

How Do You CNC Aluminum Extrusions?

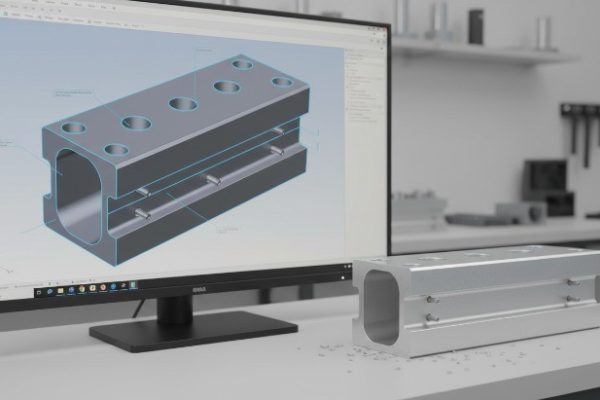

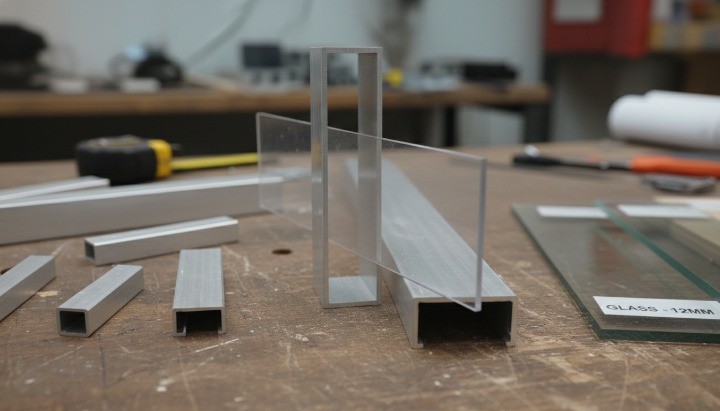

CNC machining aluminum extrusions means performing secondary precision operations on pre-extruded perfiles de aluminio. The extrusion process creates a constant cross-section. CNC machining adds features the die cannot produce.

In OEM production, CNC machining is typically used to:

- Create holes, slots, pockets, and threads

- Machine end faces and connection features

- Achieve functional tolerances not possible with extrusion alone

CNC does not replace extrusion accuracy. It works on top of extrusion tolerances, which is why understanding both stages matters.

Step-by-Step CNC Aluminum Extrusion Process

1. Aluminum Extrusion and Aging

- Aluminum billets are extruded through a die

- Profiles are stretched, straightened, and cut to length

- Heat treatment (T5 or T6) stabilizes mechanical properties

2. Pre-Cut and Inspection

- Long profiles are cut into CNC-ready lengths

- Cross-section dimensions are checked

- Surface defects are screened before machining

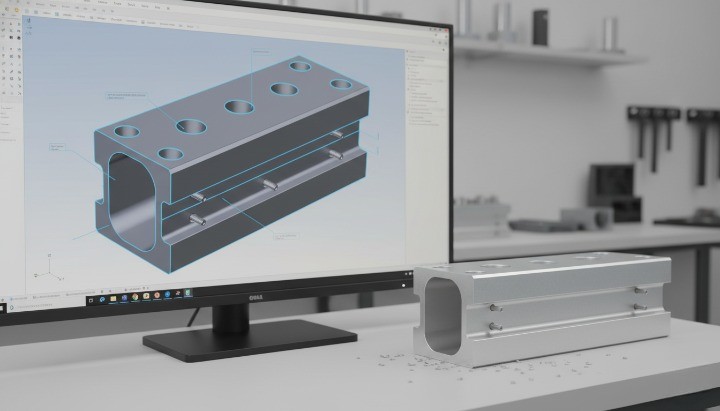

3. CNC Fixturing and Positioning

- Profiles are clamped using custom fixtures

- Datum surfaces are defined

- Incorrect fixturing is the main cause of tolerance drift

4. CNC Machining Operations

- Perforación, tapping, molienda, and end machining

- Single-side or multi-side machining depending on design

- Cycle time depends on feature count, not profile length

5. Deburring and Quality Control

- Manual or automated deburring

- Dimensional inspection

- Batch consistency verification

Common CNC Operations on Aluminum Extrusions

Typical CNC features requested by OEM buyers include:

- Perforación: mounting holes, fastener clearance

- Tapping: threaded holes for assembly

- Slot milling: adjustable tracks or channels

- Pocket milling: weight reduction or clearance

- End-face machining: precise length and squareness

- Laser marking: part numbers and traceability

Each added feature increases setup or cycle time. Grouping features on one datum face reduces cost.

Aluminum Alloys Used for CNC Machining Extrusions

The alloy affects machinability, strength, and surface finish.

| Aleación | Uso típico | CNC Machining Notes |

|---|---|---|

| 6063 | Decorative and lightweight structures | Smooth cutting, good surface finish |

| 6061 | Structural and load-bearing parts | Higher cutting forces, better strength |

| 6005A | Industrial frames | Balanced strength and machinability |

For cosmetic parts, 6063 is preferred. For mechanical strength, 6061 is more stable during CNC machining.

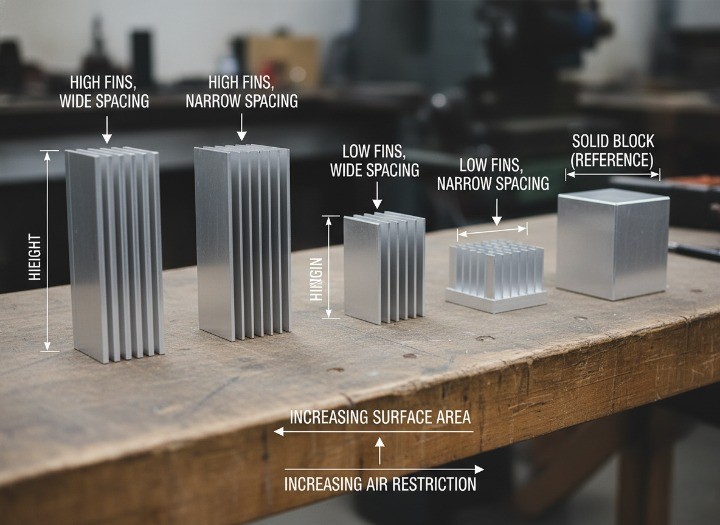

Tolerances You Can Realistically Achieve

Extrusion tolerance and CNC tolerance stack together.

| Feature Type | Typical Tolerance |

|---|---|

| Extrusion cross-section | ±0.15–0.30 mm |

| CNC hole position | ±0.05–0.10 mm |

| End-face length | ±0.10 mm |

| Thread depth | ±0.05 mm |

Key reality:

- Long profiles accumulate error

- CNC cannot correct twisted or bowed extrusions

- Over-specifying tolerance increases cost without functional gain

Fixtures and Positioning: The Hidden Cost Driver

Fixtures determine repeatability more than machine brand.

Good fixturing:

- Defines one stable datum

- Prevents profile deformation

- Allows batch machining with minimal realignment

Poor fixturing causes:

- Hole misalignment

- Scrap during batch production

- Inconsistent first article approval

For repeat OEM orders, dedicated fixtures reduce unit cost over time.

Design Tips to Reduce CNC Cost on Aluminum Extrusions

OEM buyers can reduce costs before production starts.

- Align holes and slots to one reference face

- Avoid deep pockets near thin walls

- Keep hole sizes standard where possible

- Minimize multi-side machining

- Design features to match extrusion geometry

A well-designed profile often reduces CNC time by 20–40%.

Lead Time, MOQ, and Production Planning

- Extrusion die lead time: 7–14 days

- CNC sampling: 3–5 days

- Mass production: depends on feature density

Typical MOQs:

- Extrusion only: low

- Extrusion + CNC: higher due to setup and fixtures

For a stable supply, plan CNC machining after extrusion approval, not in parallel.

When CNC Is Not the Right Choice

CNC machining is not always necessary.

Avoid CNC when:

- Features can be integrated into the extrusion die

- Tolerance is non-functional

- Volume is too low to justify fixtures

Alternatives include die optimization or standardized profiles.

What OEM Buyers Should Remember

CNC machining of aluminum extrusions is not just a post-process. It is part of a system that starts with profile design. Projects succeed when extrusion, fixturing, and CNC are planned together—not treated as separate steps.

Start Your CNC Aluminum Extrusion Project with Confidence

If you are sourcing aluminum extrusions with CNC machining, provide:

- Application requirements

- Functional tolerances

- Estimated order volume

Clear input upfront leads to faster quotes, stable pricing, and predictable delivery.