O alumínio não possui uma cor única e fixa.

O que você vê depende da liga metálica, do acabamento da superfície e de como o produto é fabricado. Para marcas OEM e compradores de varejo, entender isso ajuda a reduzir reclamações sobre cores, devoluções e retrabalho.

Este guia explica alumínio’A cor natural, como os acabamentos alteram sua aparência e como especificar a cor em pedidos em grande quantidade.

A cor natural do alumínio

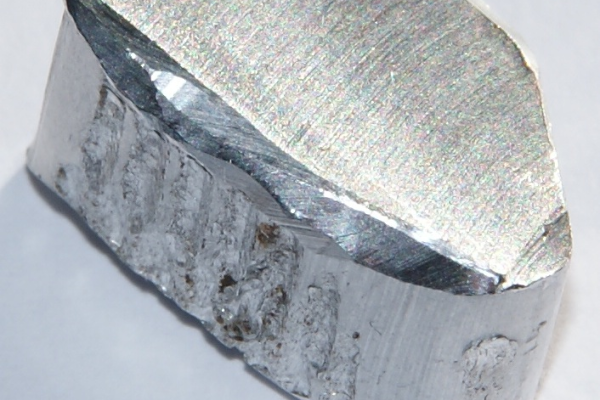

Em seu estado não tratado, o alumínio parece cinza-prateado claro.

- O alumínio recém-cortado tem uma aparência brilhante e metálica.

- Uma fina camada de óxido natural se forma instantaneamente no ar.

- Essa camada de óxido protege o alumínio, mas suaviza ligeiramente o brilho.

Diferentes ligas refletem a luz de maneiras diferentes. Por exemplo, Alumínio 6063 geralmente parece mais suave e brilhante do que 6061, mesmo antes do tratamento da superfície.

Para os compradores, isto significa: “"Cor natural do alumínio" é uma descrição visual, não um padrão controlado.

O alumínio é prateado ou cinza?

Ambas as descrições estão corretas, mas incompletas.

- Prata descreve a refletividade

- Cinza descreve o tom base

- A iluminação e a textura da superfície afetam o que seus olhos veem.

Em termos de aquisição, “prata” é não é uma especificação. Dois fornecedores podem enviar "alumínio prateado" que pareça diferente quando colocados lado a lado.

Se a cor é importante para o seu produto ou marca, você precisa de mais detalhes do que uma única palavra.

Alumínio com acabamento natural: cor versus realidade

O alumínio com acabamento de fábrica é alumínio. ao sair do processo de extrusão, sem nenhum tratamento de superfície adicional.

Aparência típica do acabamento de fábrica:

- Tom cinza-prateado claro

- Linhas de extrusão finas

- ligeira variação de brilho ao longo do comprimento.

Para produtos OEM e de varejo, o acabamento de fábrica apresenta riscos:

- A consistência da cor varia de lote para lote.

- As marcas na superfície são visíveis sob a iluminação da loja.

- Os clientes do varejo frequentemente o veem como "inacabado".“

O acabamento de fábrica é mais adequado para peças internas ou projetos com restrições de custo — não para postes de piscina destinados ao consumidor final.

Como os acabamentos de superfície alteram a cor do alumínio

O tratamento de superfície define a aparência final do alumínio mais do que o próprio metal.

Alumínio anodizado

A anodização engrossa a camada de óxido natural.

Para produtos de uso externo, como postes de piscina, a anodização melhora a estabilidade da cor sob o sol e produtos químicos.

Revestimento em pó ou alumínio pintado

Isso adiciona uma camada colorida sobre o metal.

- Maior variedade de cores

- Forte consistência visual

- Melhor opção para combinar com as cores da marca.

Desvantagem: custo mais elevado e quantidade mínima de encomenda (MOQ) mais alta.

Por que a consistência de cores é importante em pedidos de varejo e OEM

A variação de cor é uma das Principais causas de rejeição no varejo.

As causas comuns incluem:

- Diferentes lotes de alumínio

- Tanques ou tempos de anodização diferentes

- Variação da liga entre fornecedores

Compradores profissionais evitam problemas ao:

- Aprovação de amostras físicas

- Definir claramente o tipo de acabamento

- Definição de tolerância de cor aceitável (ΔE)

Na Xingyong, a consistência da cor é verificada usando iluminação controlada e ferramentas de medição antes do envio.

Exemplo real: postes de alumínio para piscinas de uso externo

Cabos de limpeza de piscinas ficam expostos a:

- luz solar UV

- Água clorada

- manuseio constante

Sem tratamento de superfície adequado:

- As cores perdem o brilho com o tempo.

- A superfície fica calcária.

- A discrepância visual entre as seções é evidente.

A anodização de alta qualidade reduz esses problemas e mantém a aparência uniforme do poste nas prateleiras das lojas.

Como especificar a cor do alumínio em pedidos OEM

Evite termos vagos como “alumínio prateado.”

Use uma destas opções:

- “Alumínio 6063, anodizado transparente, acabamento fosco.”

- “Alumínio anodizado, cor champanhe, amostra aprovada”

- “Alumínio com revestimento em pó, RAL 9006”

Sempre confirme com:

- Amostras de pré-produção

- Referências de cores aprovadas

- Descrição do acabamento por escrito no pedido de compra.

Isso economiza tempo, dinheiro e evita disputas futuras.

Perguntas frequentes: Dúvidas comuns dos compradores sobre a cor do alumínio

O alumínio é sempre prateado?

Não. Sua aparência depende do tratamento da superfície.

O alumínio muda de cor com o tempo?

O alumínio sem tratamento perde o brilho. O alumínio anodizado mantém-se estável por mais tempo.

Por que dois postes de alumínio têm aparências diferentes?

Diferentes lotes, ligas ou processos de acabamento.

O alumínio anodizado é mais escuro que o alumínio bruto?

Geralmente sim, mas a espessura e o tipo de acabamento importam.

Por que trabalhar com um fabricante de alumínio experiente?

Em projetos de varejo e OEM de grande volume, o controle de cores não é opcional.

A Xingyong produz artigos de alumínio desde 2002, com processos internos de extrusão, anodização, usinagem e inspeção. Isso permite um controle mais rigoroso sobre a aparência, a consistência e a entrega.

👉 Saiba mais sobre a nossa fabricação de postes de alumínio para piscinas.

Chamada à ação

- Solicite uma amostra de cor.

- Discuta seus requisitos de acabamento OEM.

- Obtenha orientação técnica antes da produção em massa.

Entre em contato com nossa equipe de exportação para evitar problemas dispendiosos de cor em seu próximo pedido.