Many buyers know aluminum U channel is widely used, but few understand why it is chosen ou when it truly fits a project. In OEM manufacturing, using the wrong profile often leads to loose panel fits, extra fasteners, or rising assembly costs. These problems rarely come from machining quality. They usually come from incorrect perfil selection at the design stage. This guide explains what aluminum U channel is used for, how it performs in real applications, and how to choose the right size, alloy, and finish for bulk and OEM sourcing.

What Is Aluminum U Channel Used For?

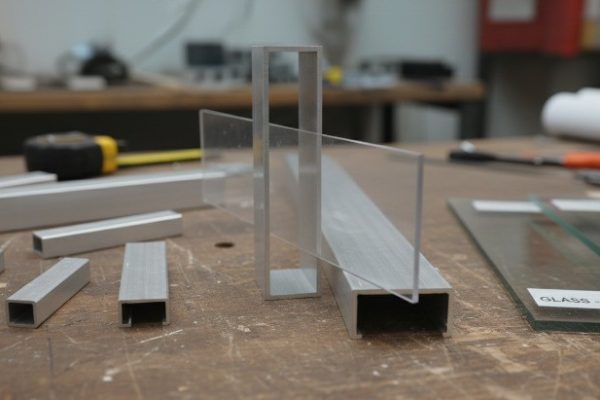

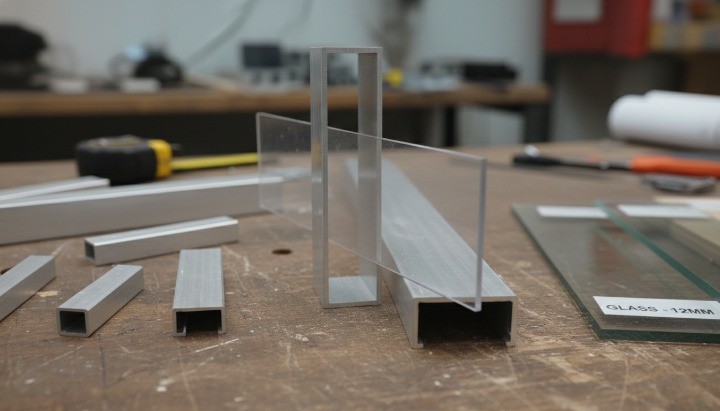

Aluminum U channel is used to frame, guide, hold, or protect flat panels and components along a straight edge.

Its U-shaped cross-section forms a controlled slot that secures materials while keeping weight low and installation simple.

In real manufacturing and construction use, aluminum U channel is applied to:

- Panel edging and protection for glass, acrylic, wood, and composite boards

- Light structural framing where alignment matters more than heavy load

- Guide tracks for sliding or insert-fit components

- Decorative trim that also provides mechanical support

Because it is typically produced by alumínio extrusão, U channel offers consistent dimensions, clean surfaces, and easy customization for OEM production.

Common Applications of Aluminum U Channel

Aluminum U channel solves two practical problems at once: alignment and edge protection. This is why it appears across construction, industrial equipment, and retail systems.

Construction and Architectural Use

In construction, aluminum U-channel is mainly used as a functional trim and framing element rather than a primary structure.

- Interior wall panels and partitions

- Glass and acrylic panel edging

- Door, window, and ceiling trim systems

Typical profiles use Alumínio 6063 com anodizado ou revestido a pó finishes for appearance and corrosion resistance. Slot widths often range from 10–30 mm, depending on panel thickness.

Industrial Equipment and Machine Frames

Manufacturers use aluminum U channel to support or guide components without adding unnecessary mass.

- Machine guards and protective covers

- Linear guide supports

- Cable routing and panel enclosures

For these applications, buyers often specify thicker wall sections ou Alumínio 6061 to improve mechanical strength and durability.

Furniture, Shelving, and Display Systems

U channel is widely used in modular furniture and retail displays because it allows fast assembly and clean lines.

- Shelving edge supports

- POP display frames

- Modular aluminum structures

Its straight geometry simplifies cutting, perfuração, and batch assembly, which helps reduce labor cost in OEM production.

Transportation and Marine Applications

In transport and marine environments, aluminum U channel is chosen for corrosion resistance and weight reduction.

- Trailer and vehicle interior framing

- Marine panel edging

- Equipment housings

Anodizado finishes are commonly specified for humid or outdoor use.

Why Aluminum U Channel Is Chosen Over Other Profiles

Aluminum U channel is not interchangeable with every aluminum profile. It is selected because its shape performs a specific function.

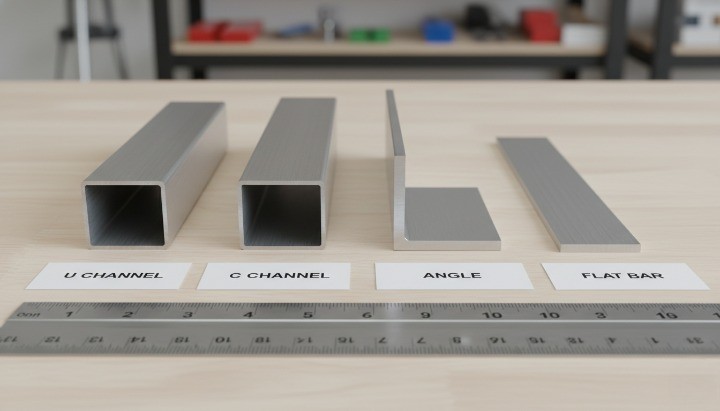

| Profile Type | Uso típico | Key Limitation |

|---|---|---|

| U Channel | Panel holding, guiding, edging | Limited torsional strength |

| Angle Aluminum | Corner reinforcement | No panel retention |

| C Channel | Structural framing | Higher material cost |

| Flat Bar | Spacers and brackets | No guiding function |

U channel is preferred when panels must be held securely without complex fasteners.

This reduces part count and speeds up assembly in batch production.

Aluminum U Channel Sizes and Tolerances

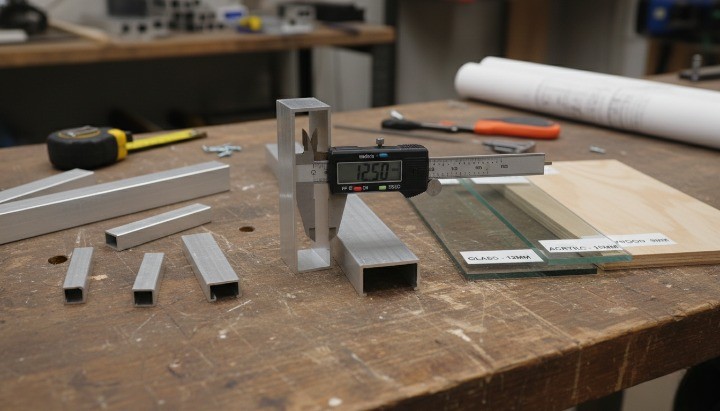

Aluminum U channel sizes are defined by slot width, leg height, and wall thickness.

Common Size Ranges

- Slot width: 6 mm – 50 mm

- Leg height: 10 mm – 80 mm

- Wall thickness: 0.8 mm – 3.0 mm

Why Tolerance Matters in OEM Orders

In extrusion, tolerance directly affects:

- Panel fit and insertion force

- Assembly speed

- Scrap rate and rework

For most OEM applications, extrusion tolerances of ±0.1–0.3 mm are standard. Tighter tolerances increase tooling complexity and production cost.

Alloy and Surface Finish Options by Use Case

Common Aluminum Alloys

6063 Aluminum

Used for architectural, decorative, and general framing applications. It offers good corrosion resistance and superior surface finish.6061 Aluminum

Used for industrial or load-related applications. It provides higher strength with slightly lower surface appearance quality.

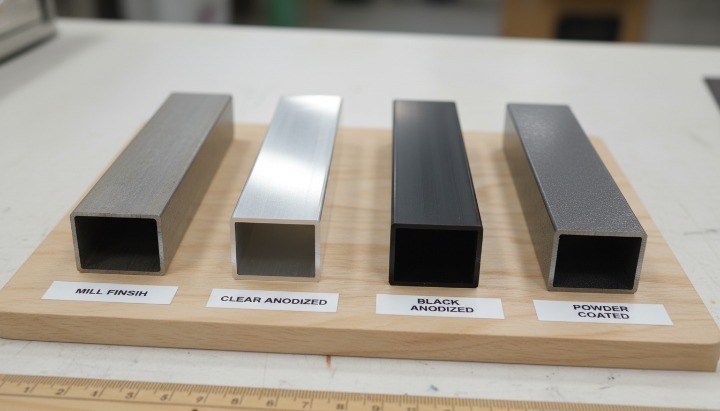

Surface Finish Options

| Finish Type | Uso típico |

|---|---|

| Acabamento de fábrica | Internal or hidden components |

| Anodizado | Outdoor and architectural use |

| Revestido com pó | Decorative and branded products |

| Brushed / sandblasted | Visible furniture and displays |

Finish selection should match the environment, not just appearance.

Why Aluminum U Channel Is Almost Always Extruded

Aluminum U channel is almost always produced by extrusion because this method offers:

- Stable cross-sections over long lengths

- Cost efficiency for medium and high volumes

- Easy customization through extrusion tooling

Producing the same shape by machining from solid aluminum would significantly increase material waste and unit cost.

How to Choose the Right Aluminum U Channel

When sourcing aluminum U channel for OEM or bulk production, buyers should evaluate:

- Load and structural requirement

- Panel thickness and fit method

- Indoor vs outdoor environment

- Surface finish durability

- MOQ, tooling, and lead time

Selecting the correct profile early reduces redesign, delays, and downstream assembly issues.

Common Buyer Mistakes

- Choosing wall thickness without load evaluation

- Over-specifying alloy strength and increasing cost

- Ignoring finish performance in outdoor environments

- Assuming all U channels are interchangeable

These mistakes usually result in higher total cost, not better performance.

FAQs About Aluminum U Channel

Is aluminum U channel structural?

It can be used in light structural applications but is not designed for heavy load-bearing frames.

Can aluminum U channel be welded?

Yes. 6061 aluminum welds more easily than 6063.

Is anodized aluminum U channel suitable for outdoor use?

Yes. Anodizing significantly improves corrosion resistance.

Can aluminum U channel be customized for OEM orders?

Yes. Custom extrusion tooling is common for volume production.

Why the Right U Channel Simplifies Manufacturing

Aluminum U channel works best when treated as a functional design element, not a generic trim. The right size, alloy, and finish reduce fasteners, simplify assembly, and improve consistency across production batches. For OEM buyers, this often lowers total cost even if the profile itself appears similar.

Talk to an Aluminum Extrusion Manufacturer

For OEM or bulk sourcing, working directly with an aluminum extrusion manufacturer allows better control over profile design, surface finish, tolerance, and delivery schedule. This approach is especially important when consistency and long-term supply stability matter.