Overheating is one of the fastest ways to shorten the life of electronic products. LEDs dim early. Power supplies derate. Control systems fail in the field. Many of these problems trace back to one decision: the wrong heat sink. For OEM buyers, choosing a cooling solution is not only a thermal issue, but also a sourcing and production decision. An extruded heat sink is often the default option, but not always the right one. This guide explains what an extruded heat sink is, how it is made, and how OEM buyers should evaluate it for volume production, cost control, and long-term supply stability.

What Is an Extruded Heat Sink and When OEM Buyers Use It

Um dissipador de calor extrudado é um heat dissipation component made by forcing heated aluminum through a shaped die, creating a long profile with a constant cross-section and integrated fins.

OEM buyers typically choose extrusion when:

- The heat sink has a linear or rectangular profile

- Production volumes are medium to high

- The design must be repeatable and stable over long runs

- Cost per unit matters more than complex 3D geometry

Because the cross-section is fixed, extrusion delivers predictable thermal and mechanical performance across thousands or millions of parts.

How Extruded Heat Sinks Are Made

Extruded heat sinks follow a controlled, repeatable manufacturing process.

Aluminum extrusion process

- Aluminum billets are heated to around 450–500°C

- The billet is pushed through a hardened steel die

- A continuous perfil exits the die with fins and base already formed

- O perfil é resfriado, endireitado e cortado no comprimento desejado.

Secondary processing

Most OEM heat sinks require additional steps:

- CNC perfuração or tapping for mounting holes

- Moagem slots or cutouts

- Deburring to protect wiring and assembly workers

- Surface finishing such as anodização

This combination of extrusion plus machining is what makes extruded heat sinks flexible for OEM applications.

Materials and Finishes Used in Extruded Heat Sinks

Common aluminum alloys

Most extruded heat sinks use:

- Aluminum 6063-T5 for good thermal conductivity and excellent extrudability

- Aluminum 6061 when higher strength is required, with trade-offs in surface finish

6063 is widely preferred because it balances:

- Smooth surface after extrusion

- Consistent anodizing results

- Stable dimensional control in long profiles

Surface finishes

Common finish options include:

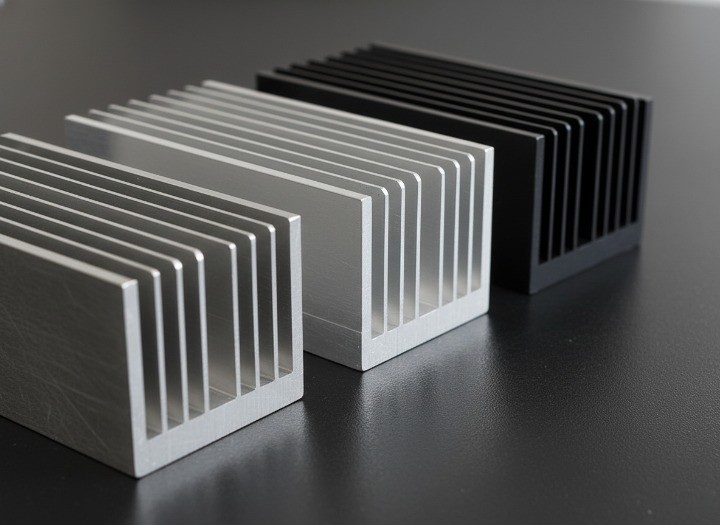

- Mill finish for lowest cost

- Clear anodizing for corrosion resistance

- Black anodizing to improve thermal radiation and visual uniformity

For natural convection systems, black anodizing can improve heat dissipation. In forced-air systems, airflow design matters more than color.

Design Rules That Affect Cost and Performance

Poor design assumptions cause redesigns, tooling changes, and delayed launches. OEM buyers should understand these constraints early.

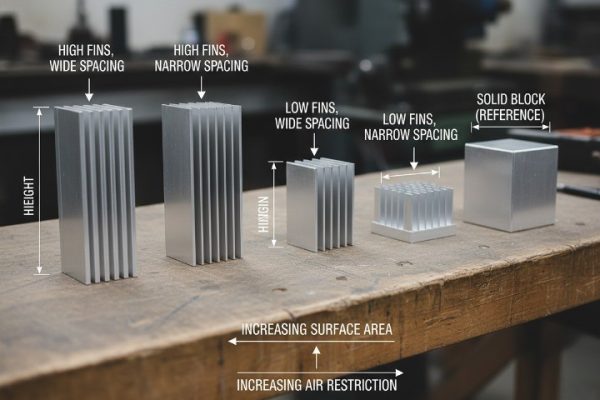

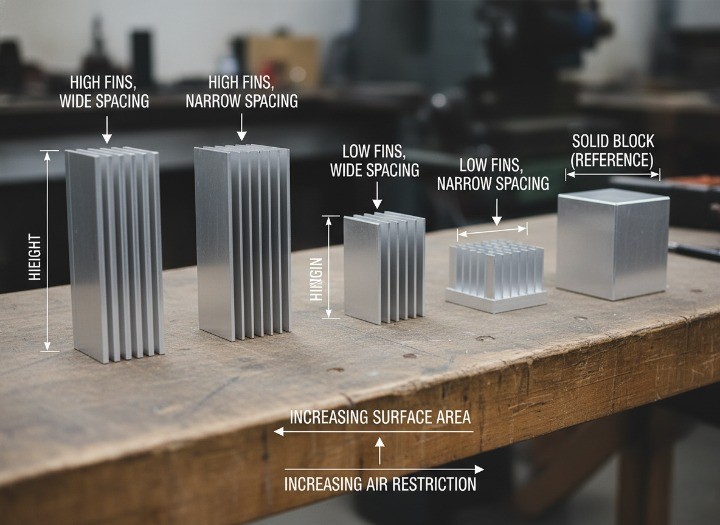

Fin spacing and height

- Very thin fins increase die risk and extrusion cost

- Extremely tight fin spacing can reduce airflow efficiency

- Fin height is limited by extrusion stability and straightness

Base thickness

- Thicker bases spread heat better

- Thinner bases reduce weight and material cost

- Flatness requirements should match the thermal interface material used

Orientation and airflow

- Vertical fins work best for natural convection

- Parallel fins align better with forced airflow

- Dense fin designs require fan pressure analysis

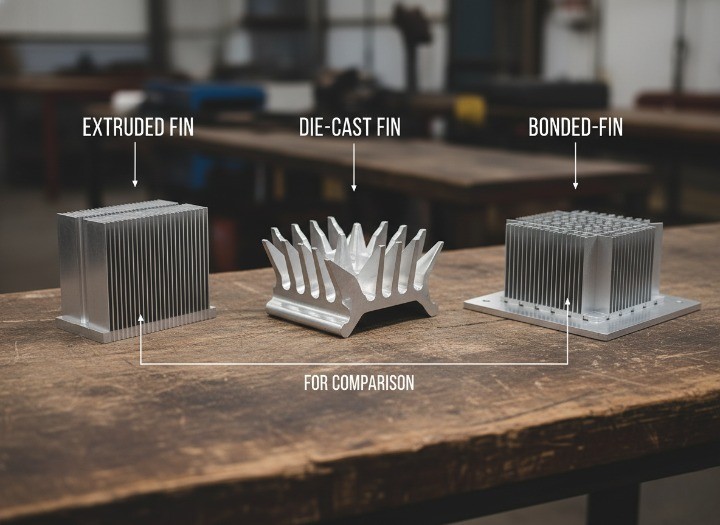

Extruded vs Die-Cast vs Bonded-Fin Heat Sinks

OEM buyers often compare multiple heat sink technologies before locking a design.

Comparison table

| Type | Best use case | Tooling cost | Shape freedom | Unit cost at scale |

|---|---|---|---|---|

| Extruded heat sink | Linear profiles, repeat orders | Baixo | Médio | Baixo |

| Die-cast heat sink | Complex shapes, integrated features | Médio | Alto | Médio |

| Bonded-fin heat sink | High power density cooling | Baixo | Alto | Alto |

Extrusion works best when the profile can stay simple and production volumes justify the die investment.

OEM RFQ Checklist for Extruded Heat Sinks

A clear RFQ reduces quoting cycles and avoids surprises.

What to include

- 2D drawing with critical tolerances

- 3D CAD file of the heat sink

- Thermal requirements: wattage, target temperature rise, airflow

- Finish requirements and cosmetic expectations

- Mounting method and fastener details

What buyers often miss

- Flatness requirements at the contact surface

- Anodizing thickness tolerance

- Packaging to protect fins during shipment

- Inspection method and acceptance criteria

Providing this upfront helps suppliers quote accurately and quickly.

Cost Drivers and MOQ Logic

Understanding cost structure helps buyers negotiate effectively.

Main cost factors

- Extrusion die cost (one-time)

- Profile size and aluminum weight

- CNC machining content per part

- Surface finish and masking requirements

- Packaging and inspection level

MOQ considerations

- Lower MOQs increase per-unit cost

- Existing dies reduce tooling expense

- Repeat orders stabilize pricing and lead time

OEM buyers often request two quotes: one using a standard profile and one with a custom die.

Quality Control Points for OEM Buyers

Before shipment, buyers should align on inspection standards.

Key checks include:

- Alloy verification using spectrometer testing

- Dimensional inspection of fin spacing and base thickness

- Flatness measurement at mounting surface

- Visual inspection for scratches and anodizing defects

For automotive or regulated applications, PPAP or IATF-style documentation may be required.

!alt aluminum heat sink inspection and quality control tools

Lead Time and International Trade Considerations

Typical lead times:

- New extrusion die and first samples: 3–5 weeks

- Repeat orders with existing die: 2–3 weeks

Trade considerations:

- HS code classification for aluminum profiles

- Packaging design to avoid fin damage in transit

- Clear Incoterms to define responsibility and cost

Early alignment on these points avoids customs delays and damage claims.

Common Questions OEM Buyers Ask

Is an extruded heat sink better than a machined one?

Extrusion is more cost-effective for volume. Fully machined heat sinks are used for prototypes or low-volume runs.

Does black anodizing always improve cooling?

It helps with radiation in natural convection. In forced-air systems, airflow dominates performance.

Can fin spacing be changed later?

Only by modifying or replacing the extrusion die, which adds cost and time.

What files are needed for quoting?

A 2D drawing, 3D model, and thermal requirements are usually sufficient.

A Practical Way to Decide

Choose an extruded heat sink if:

- Your design has a constant cross-section

- You expect repeat orders

- You want predictable cost and performance

- You can manage secondary machining separately

If geometry becomes complex or integration is required, consider die casting or bonded-fin designs instead.

Talk to an OEM Extrusion Partner

If you are sourcing extruded heat sinks for production, share your drawing, target wattage, and airflow conditions. A qualified supplier can review feasibility, estimate tooling, and suggest profile optimizations before you commit.