Guide pratique pour les fabricants d'équipement d'origine et les acheteurs commerciaux

Le forage de poteaux de clôture en aluminium dans des bordures en béton est une pratique courante. projets commerciaux, municipaux et de piscine. Il est esthétique, peu encombrant et répond à de nombreuses contraintes d'installation. Mais du point de vue des équipementiers et des achats, ce détail est aussi l'un des… sources les plus courantes de retouches, de retards et d'échecs d'inspection.

Ce guide explique détail du forage carotté dans la bordure clairement — avec des dimensions réelles, les risques sur le terrain et les contrôles de fabrication que les acheteurs devraient confirmer avant La production commence.

Ce que signifie réellement le forage carotté dans une bordure (pour les acheteurs)

Le carottage crée un trou rond dans le béton durci afin que le poteau de clôture en aluminium puisse être inséré directement dans le caniveau et fixé avec du coulis.

Du point de vue de l'acheteur, ce détail est important car :

- Les bordures sont plus étroit et plus faible que des dalles.

- De petites erreurs dimensionnelles peuvent fissurer le trottoir.

- Il faut prendre des décisions concernant la longueur du poteau et l'arrivée. au stade de l'usine.

Si la méthode d'installation n'est pas claire lors de l'approvisionnement, les poteaux arrivent souvent trop courts, les revêtements sont endommagés sur place ou les inspecteurs rejettent les travaux.

Quand le forage carotté est le bon choix (et quand il ne l'est pas)

Carottage Il est généralement choisi pour les projets où l'espace et l'esthétique sont importants.

Projets typiques où cela fonctionne bien

- Clôtures et barrières de sécurité pour piscines commerciales

- Clôtures en aluminium pour écoles, parcs et municipalités

- Sites commerciaux ou hôteliers avec trottoirs étroits

Situations dans lesquelles les acheteurs devraient faire une pause

- Bordures très peu profondes ou décoratives

- Bordures de trottoir dont le renforcement est inconnu

- Projets nécessitant des clôtures amovibles ou temporaires

Dans ces cas-là, le montage en surface ou les manchons intégrés peuvent réduire les risques, même si le coût initial est plus élevé.

Dimensions typiques des forets à carottage pour poteaux de clôture en aluminium

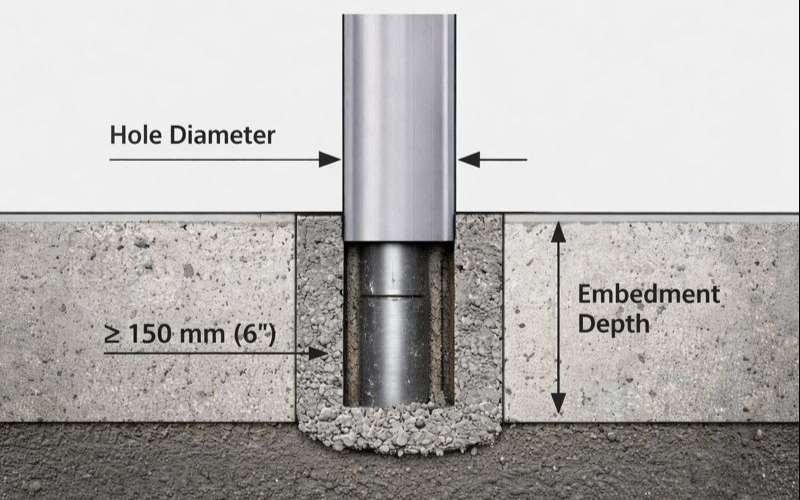

La plupart des problèmes d'installation proviennent d'un diamètre de trou ou d'une profondeur d'encastrement incorrects. Bien que les normes locales varient, de nombreux projets commerciaux respectent ces plages pratiques.

plages de référence courantes

- Diamètre du trou : diamètre extérieur du poteau + 10–20 mm (≈ 3/8″–3/4″ de dégagement)

- Profondeur d'immersion : 100–150 mm (4″–6″)

- Hauteur minimale du trottoir : ≥150 mm (6″)

Exemple

- Poteau en aluminium : 50 × 50 mm (2″ × 2″)

- Trou de carottage : diamètre de 65 à 75 mm

- Profondeur d'encastrement : ~125 mm

Ces dimensions permettent une couverture adéquate du coulis tout en conservant suffisamment de béton autour du trou.

Clôtures en aluminium : facteurs spécifiques souvent négligés dans les guides

La plupart des guides en ligne sont conçus pour les poteaux en acier. L'aluminium se comporte différemment, et les acheteurs doivent en tenir compte dès le départ.

Considérations clés spécifiques à l'aluminium

- Un poids plus léger signifie La qualité du coulis compte davantage

- Les poteaux à paroi mince peuvent se déformer s'ils sont forcés ou coincés.

- revêtement en poudre et anodisé Les finitions nécessitent une protection près de la base

Chez Xingyong, ces facteurs influencent le choix de l'alliage, l'épaisseur de la paroi et la nécessité d'un traitement de surface spécial pour les sections enterrées.

Distance au bord du trottoir et risque de fissures (Pourquoi les inspecteurs refusent des chantiers)

Les bordures fissurées constituent l'un des points de défaillance les plus courants des clôtures fixées sur bordure.

Règles de terrain couramment utilisées

- Distance minimale au bord : 1,5 fois le diamètre du trou

- Évitez de percer à l'intérieur 50 mm (2″) bords de trottoir

- Aucune charge latérale pendant le forage

Une fois qu'une bordure de trottoir est fissurée, les réparations sont visibles et souvent refusées lors des inspections commerciales, même si la clôture elle-même est droite.

Jointoiement et mise en place : là où se gagne ou se perd la stabilité à long terme

Un trou propre et un joint approprié font toute la différence entre une clôture solide et des interventions nécessaires des mois plus tard.

meilleures pratiques

- Enlever toute la boue et la poussière avant la mise en place

- Utilisez un coulis cimentaire sans retrait ou à haute résistance.

- Mettez les poteaux d'aplomb et vérifiez à nouveau pendant le durcissement initial

- Évitez de charger les poteaux jusqu'à ce que le temps de séchage complet soit atteint.

Négliger cette étape est l'une des principales causes de la desserrement des poteaux dans les clôtures en aluminium.

Ce que les acheteurs OEM doivent vérifier avant la production

C’est là que de nombreux projets commerciaux échouent – non pas sur le chantier, mais au moment de la commande.

Avant de confirmer la production, les acheteurs doivent définir clairement :

- Longueur finale du message, y compris la profondeur d'immersion

- Que les poteaux soient coupés en usine ou sur place

- Exigences de finition pour les sections enterrées

- attentes en matière de rectitude et de tolérance

En tant que fabricant produisant plus de 3 000 tonnes de profilés en aluminium par mois, Xingyong ajuste régulièrement la longueur des poteaux, l'épaisseur des murs et les détails de finition en fonction de ces données d'installation.

Problèmes courants sur le terrain (et comment les acheteurs peuvent les prévenir)

Problème : Les poteaux semblent lâches après l'installation

- Souvent causé par des trous trop grands ou un mauvais choix de coulis

Problème : Dommages au revêtement à la base

- Généralement dû au perçage sans protection de surface

Problème : Les panneaux de clôture ne sont pas de niveau.

- Cela se produit lorsque les publications ne sont pas revérifiées pendant la période de modération.

Chaque problème engendre des retards, des coûts de main-d'œuvre supplémentaires ou des rejets lors des inspections. Des spécifications claires permettent de réduire ces trois risques.

FAQ : Détails du perçage d'une bordure pour une clôture en aluminium

Est-il possible de fixer des poteaux de clôture en aluminium par forage carotté dans les bordures de trottoir ?

Oui. Cette méthode est largement utilisée dans les projets commerciaux et municipaux lorsque les dimensions des bordures permettent un encastrement adéquat.

À quelle profondeur faut-il installer les poteaux en aluminium ?

La plupart des projets utilisent un encastrement de 100 à 150 mm, en fonction de la hauteur du trottoir et des exigences de charge.

Cette méthode est-elle conforme au code ?

En règle générale oui, mais la conformité dépend des codes du bâtiment locaux et des spécifications du projet.

Qui est responsable de la définition du diamètre du trou ?

Les installateurs percent les trous, mais les fournisseurs doivent connaître la méthode d'installation pour fournir les poteaux de longueur adéquate.

Vous prévoyez un projet de clôture commerciale en aluminium ?

Si votre projet implique clôture en aluminium montée sur trottoir, Une coordination précoce permet de gagner du temps et de réduire les coûts.

Avant de commander, partagez :

- Dimensions du trottoir et méthode d'installation

- Profondeur d'encastrement requise

- Exigences de finition et d'inspection

Demander un échantillon.

Envoyez votre dessin pour évaluation.

Veuillez contacter notre équipe export pour confirmer les détails de production avant de passer commande.